The Best 3D Printer for Your Project: Comparison of the Most Popular Models

One of the best ways to reduce your prototyping costs and speed up your time to market is to purchase your own 3D printer. But which is best for your tech product?

Written by Alex Berrou who is a mechanical engineer and one of the experts available to help you inside the Hardware Academy.

It always takes several iterations to get your product enclosure design, or any other custom plastic parts, just right. In fact, it usually takes many more prototype iterations than you expect.

This is why having your own 3D printer can be such a powerful benefit. Not only can you essentially print your own parts for very little cost, you can also iterate your design much faster.

The flexibility to make a design change then have a sample in your hands within hours allows you to finalize your design much faster which means you make it to market much faster as well.

The quality of your parts won’t typically be as high as a professional supplier, but they will be more than sufficient especially for your early prototypes. Once you finalize the design with your own printer, then you can always later upgrade to professional printed parts.

This article only reviews printers with a heated print bed, since those without are barely acceptable for hobby projects.

The focus of this article is on “desktop” 3D printers, since the high price of industrial printers means that they are only justified for mass production of high quality parts.

When it came to choosing the printers on this list, the focus was on popular and well-established brands, with enough user feedback and reviews to truly judge their quality.

This leads to a very important note: do not ever put your trust solely in professional reviews. Most review sites depend on manufacturers to send them free printers for testing, and will essentially never give a negative opinion.

All of the printers on this list were ranked “best of the year” by several major sites, and yet some of them have dismal user reviews. Always consult user reviews before buying a printer.

In total we will look at 20 different 3D printers in this roundup article.

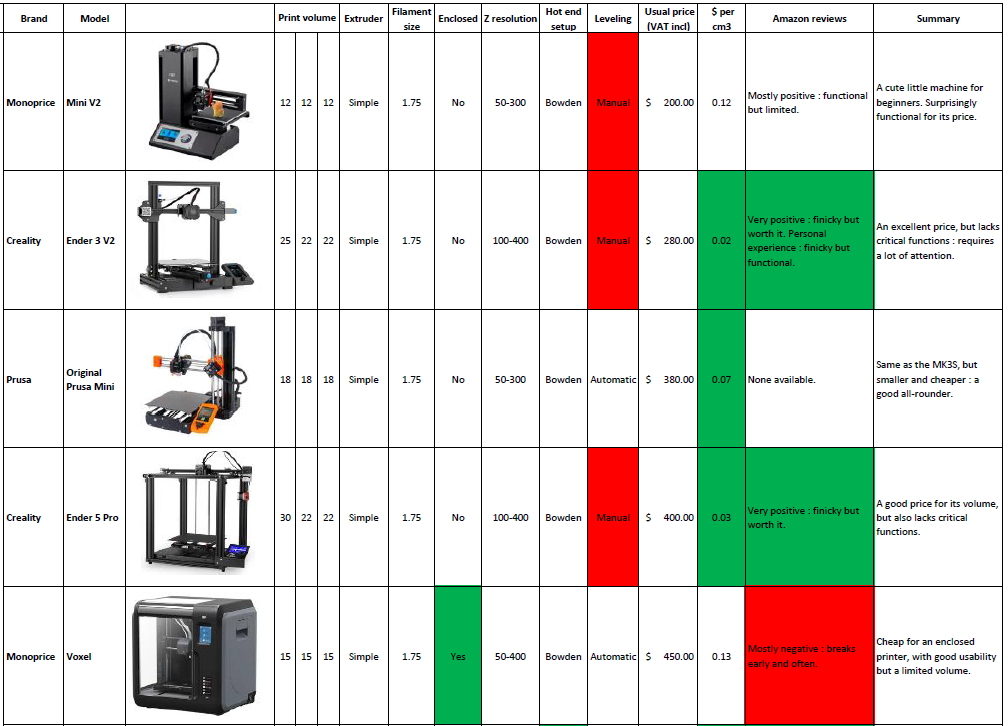

The image above is only a segment of the full comparison table. You can download the full table with all 20 printers as an Excel spreadsheet.

3D Printer Specifications

Print volume: the maximum size of the area that you can print. This is one of the main factors influencing cost.

Extruder: simple extruders are the norm, and can print one material. Dual extruders can print two, which allows multi-material prints. See “Multi-material printing” for more.

The Zmorph with its interchangeable extruder modules and the XYZ with its special ink injector are exceptions.

Filament size: 1.75mm is the most commonly used norm, followed by 2.85mm. This means that the first will allow for a slightly larger choice of filaments.

Proprietary filaments are an attempt to impose the “classic” printer paradigm on 3D printing: force the user to depend on the supplier for continued use of their device, even if their products are inferior and costlier. Avoid them. The same applies to resins.

Enclosed: a fully enclosed printer will generally be less noisy and emit fewer fumes. More importantly, the controlled temperature inside of the enclosure is necessary for the printing of some high-grade materials.

However, it is possible to build an enclosure for any printer yourself, or buy third-party ones for widespread printers. All resin printers are enclosed due to the risk of splashing and fumes.

Z resolution: this is the minimal and maximal layer thickness allowed by the machine, in microns. Smaller resolutions will make for more detailed prints, while larger ones will make printing faster. (I personally use 150 for quality prints and 300 for drafts).

This is not a critical factor, as layer thickness is barely visible in most prints, and software updates can allow new thicknesses as a printer ages.

XY resolution (resin): this is the level of horizontal detail that a resin printer allows. Most users cannot really see the difference at such a small scale.

I do not list the XY resolution for FDM printers, because changing it is a matter of screwing on a new print head. The standard dimension is 0.4mm, but sizes from 0.25mm to 0.6mm are available in order to make either more detailed or faster prints.

Hot end setup: There are two common hot end setups.

“Direct” is where the motor that pushes the filament into the print head is directly attached to this print head.

“Bowden” is where the motor is fixed on the printer’s body and pushes the filament into a Bowden tube, which guides it to the print head. Direct drives are heavier on the print head, and thus require a stronger structure.

Bowdens, on the other hand, are the cause of many breakdowns and clogs, as the filament tends to get stuck in them. Based on personal experience with both technologies, I only trust direct drives.

Leveling: this is the action by which a printer detects the level of the print bed, and calibrates its height accordingly. Leveling before each print is advised for quality purposes, but manual leveling is a time-consuming process. Having to do it repeatedly can be a serious issue if you print often.

$ per cm3: the price divided by the print volume. This is a good indicator of a printer’s relative value, and whether its price is justified.

Amazon reviews: the most important factor in my opinion, as explained earlier user reviews are the only real way to judge a printer’s quality.

Professional reviewers cannot be fully trusted for this. I have also described my personal experience for any printers that I own.

Cloned Printers

You will find many “clones” of 3D printers online. These are copies of existing printers, generally originating from Chinese intellectual property theft, sold for a lower price than the original.

The most commonly copied models are the Prusa and Ender (amusingly, Ender started out as a Prusa knockoff, before growing into its own), hence Prusa’s insistence on the “Original Prusa” tag.

If you are lucky, these ersatz may be just as functional as the real products, since they are often copied and sold by the same factories that make the originals. However, you will lose out on software updates, warranties and bug fixes.

More importantly, you will be actively financing and encouraging theft, as opposed to innovation, in a field that is still largely dominated by creative start-ups and not major corporations.

Multi-Material Printing

The ability to print multiple materials simultaneously is one of the main selling points of the costly “dual extruder” printers. There are alternatives at a much lower price.

The $500 Mosaic Palette 2 is an add-on that is compatible with most printers and allows for the use of four filaments simultaneously. The $300 Prusa MMU2 is an add-on for the MK3 specifically that ups the game to five filaments.

These printers are slightly less reliable since they are more complex, but they allow for some very interesting creations (multicolor, mixing material properties, using soluble support materials, etc.)