7 Strategies to Develop Your New Product

Discover seven strategies to get your new product developed regardless of your technical skills. There is at least one strategy for everyone.

There are multiple ways for you to develop a new physical product and bring it to market. However, the strategy that is best for you depends on your specific experience, your product, your team, and your finances. There isn’t one strategy to develop a product that is best for everyone under every situation.

In this article you’ll discover 7 different strategies that you can follow to get your product idea out of your head and on the market.

Strategy #1 – The Outsource Strategy

This strategy is for those of you who don’t have the technical skills to do any significant development on your own, yet you have the financial means to pay someone else to do it.

This is one of the more common strategies I see followed, probably because if you have the money it will be easier to make initial progress than using the other strategies we’ll discuss. For instance, finding good developers to work on your project will typically be much easier than finding co-founders or a manufacturing partner.

All of the risk is placed on you (the payer) when outsourcing product development, and the developers you hire generally have no risk since you pay them by the hour.

There are really two options when outsourcing development. You can hire individual freelancers or you can hire a design firm.

The advantage of freelancers is they’re going to be, by far, the cheapest way for you to outsource the development of your product. This is especially true if you’re able to outsource to engineers located, say, in India. They will charge less than someone in the US, for instance, or even parts of Europe or Canada.

The downside of working with freelancers is you really need technical knowledge to be able to review and judge their work. Otherwise, you have no way of determining the quality of the work being done. If you aren’t able to do this then hire an independent engineer to review their work before you pay.

Hiring a firm is going to be quite a bit more expensive than hiring individual freelancers, but it’s usually a safer option. The key advantage of hiring a firm is it’s going to be a more predictable and reliable development process because they have established processes in place. They’ve developed many, many products and they do it in an organized reliable fashion.

The other advantage is a firm will typically manage the product development. They’re going to manage all the various engineers, since multiple engineers are usually required to fully develop a product.

If you hire freelancers, then you’re going to be, or someone on your team will have to be responsible for managing all those engineers and making sure that all their pieces come together to form the final product.

Strategy #2 – The Maker Strategy

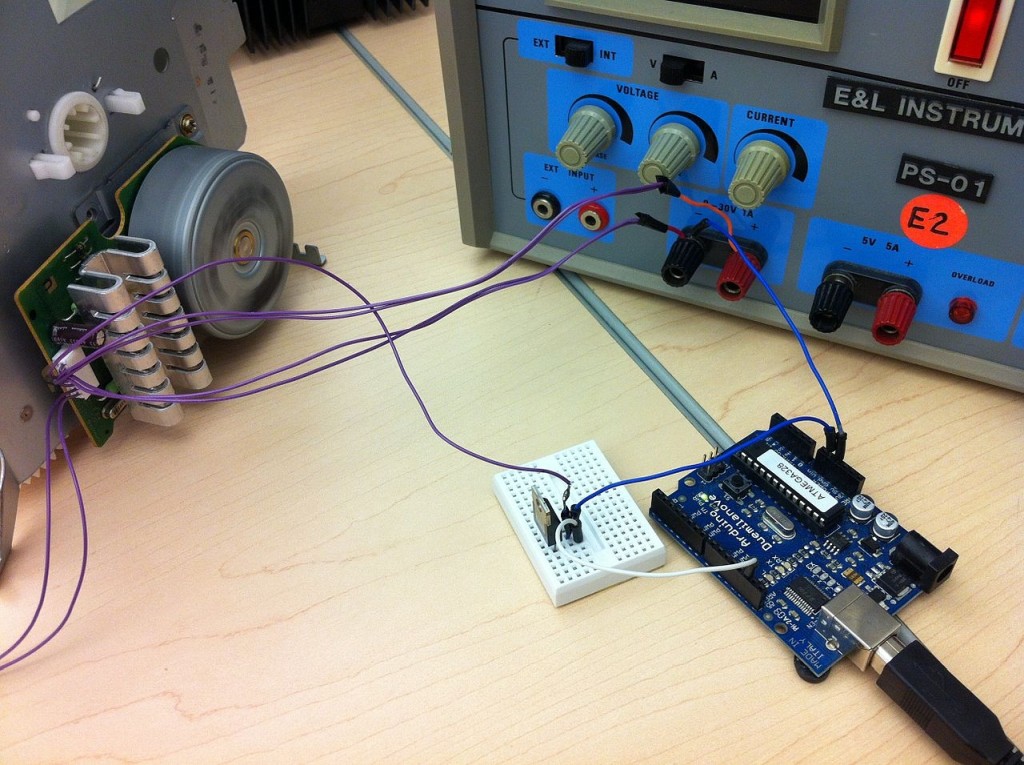

As a maker, you’re probably going to focus all of your effort on developing a Proof-of-Concept prototype. This is a prototype typically based on an electronic development kit (Arduino, Raspberry Pi, etc.) and a 3D-printed plastic enclosure.

Makers typically focus on creating a Proof-of-Concept (POC) prototype using electronic development kits (Arduino and Raspberry Pi) and 3D printers.

As the name implies, the purpose of a POC prototype is to prove the concept of the product. A proof of concept prototype can also be helpful for gathering market feedback. It’s not going to be something that you can actually take to market, but it proves the fundamental concept of the product.

Typically, a POC prototype is absolutely required only if you have major questions about your product and whether the solution you have in mind will actually solve the intended problem. However, for many products, a POC prototype doesn’t provide much additional benefit.

Makers tend to over-focus on the POC prototype. Regardless of the strategy followed, I have found that most people focus their effort on the steps they feel most comfortable performing. They don’t worry about the later steps until they’ve completed the steps they find most comfortable or rewarding.

The classic case is an engineer focusing all of their efforts on development without ever giving serious thought to sales and marketing until they finally finish development.

But don’t forget to ask yourself, what’s the next stage after the proof-of-concept? For all of these strategies to be successful, you have to know all the steps that lie ahead, you can’t just take one step at a time with no visibility of the other steps.

The majority of people get stuck where they feel most comfortable, but that’s not a recipe for success. To be a successful entrepreneur you will always need to force yourself to focus on those steps that may not feel so comfortable to you.

After you get through the Proof-of-Concept prototype stage, the next step is to develop a custom design that can actually be manufactured. Most makers are fine doing a POC prototype but not a manufacturable version of their product.

Because of this fact most makers will want to outsource the custom product design. Although, some makers may have the ability to learn these skills themselves if given enough time.

Strategy #3 – The Engineer Strategy

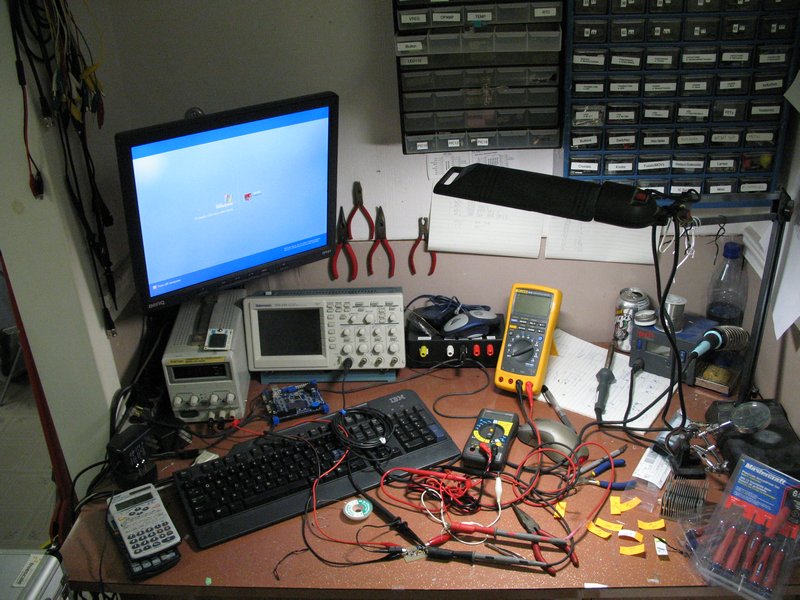

This strategy is for those of you that are engineers, particularly if you already have real-world product development experience with either electronics or plastic enclosure design.

If you’re an engineer that feels confident doing at least some of the development of your product, and you are up to learning the skills that you’re lacking, then this is going to be the cheapest way to get a product developed.

An engineer with the skills necessary to develop their own product will save significant money.

If you have the skills to do it all yourself, obviously you’re going to save a lot of money on engineering fees that you would normally pay to outsource. Regardless of your background, most engineers will not have experience in every specialty required to fully develop a commercial product.

This means you’re going to have to start off by teaching yourself any skills that you are lacking. In some cases, learning these skills yourself can be faster than outsourcing them.

For example, my own product had a large mechanical component to it. I’m an electrical engineer, so I started off hiring a mechanical engineer to do the 3D modeling. I was very frustrated with how slow things were proceeding. I felt like the project wasn’t getting the priority it deserved.

I got rid of that mechanical engineer and hired a second one who was just as slow.

The engineers didn’t seem to be devoting the time I thought my product deserved. But keep in mind, freelancers have lots of other projects that they’re working on. They’re not your full-time engineer. Most entrepreneurs aren’t exactly patient, myself definitely included, so this can be frustrating.

After two engineers and many delays I decided to just teach myself how to do 3D modeling. I also began studying injection molding, and how it relates to product design and production.

It probably took me a couple of months to get up to speed, but it ended up being much faster in the end. The design was finished much quicker because I was highly motivated. I was working on it every free moment that I had, versus a freelancer only working on it part-time. This can be a good strategy if you’re comfortable learning new things.

This strategy has the lowest financial risk because you’re not paying engineering fees. The downside with doing the product on your own is you’re most likely going to pay higher prototyping fees.

The reason is you’re more likely to make mistakes than an experienced design team. This means you will probably need to produce multiple iterations of your prototype to get everything just right.

In almost all cases, the increased prototyping costs will be more than offset by how much you save in engineering fees. The cost to develop a product is, by far, dominated by engineering fees and not prototyping costs. Prototyping can be a significant cost, but it’s not the biggest expense.

Strategy #4 – The Inventor Strategy

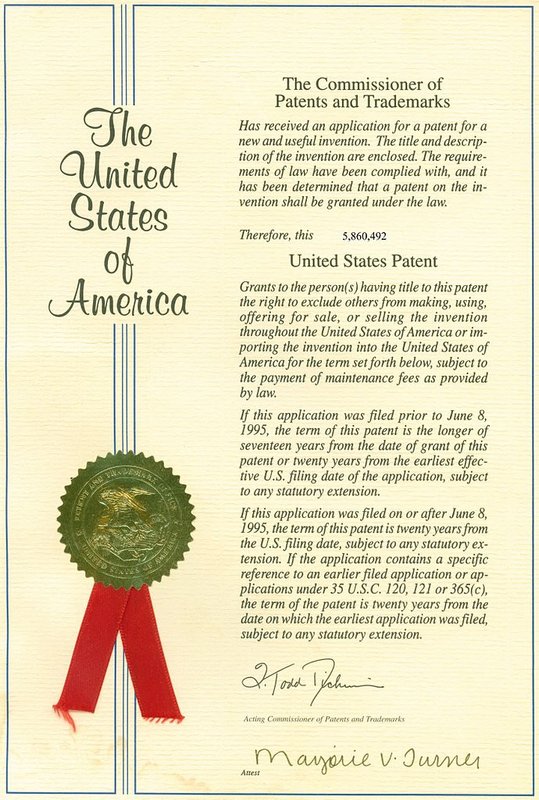

Initially, most inventors focus entirely on obtaining a patent, and perhaps later on licensing their idea. I’ll say upfront that I don’t recommend this strategy. It is, however, the strategy that I see most inventors following.

Inventors focus too much on the patent. Most patents never make it to market.

The first step that an inventor almost always focuses on is getting a patent. In my opinion, getting a patent is not the best use of your time or your money, at least initially. Patents are quite expensive. It can cost $10,000 or more to get a full utility patent.

It also takes a really long time to obtain a full patent. In 2020 the average approval time for a utility patent was 23.3 months!

You have to remember that most, or in fact nearly all, patents never make it to market. These patents never got to market because the inventor was focused on the patent instead of developing a proven product that people actually want to buy.

The problem with a patent is that you’ve starting off with the assumption that you’ve figured out the best way to solve a problem. You are assuming that you don’t need any feedback from anyone. This thinking will cause you to jump right in to spending $10,000 to hire a patent attorney.

Focusing exclusively on a patent stems from the fact that you’ve placed way too much value on your idea and not enough on the execution of that idea. The number one mistake that I see new entrepreneurs make is they overvalue their idea while undervaluing the execution of that idea.

When you focus on a patent, you’re focusing on the value of your idea. You can’t develop a product and expect it to be a success entirely in your own head. You have to get feedback from the market to find out what people really want.

I cannot stress this enough, so let me repeat it. You are making a major mistake if you feel 100% confident that you have the actual solution that people want. But that’s what you’re doing by starting with a patent.

I speak from experience, because I did the exact same thing.

I started off with a patent and even went one step further and purchased patent insurance. If someone tried to infringe on my patent, this insurance would pay any legal fees to sue that person. I made the mistake of putting way too much value on my product idea. As my mother always told me as a child “Do as I say, not as I do!”

When I was a design engineer at Texas Instruments, I worked on dozens of product development projects. In almost all those cases, the product didn’t have a patent. Many designs had portions that were sometimes patented, but never the entire product.

Instead, a large company like Texas Instruments is focused on the execution. They focus on understanding what the market wants, and developing and manufacturing the best product possible. This secures their market share, not a patent.

After getting a patent, a lot of inventors try (usually unsuccessfully) to sell or license their idea. Once again, this places too much value on the idea and not the execution. With this strategy, you’re attempting to entirely skip the execution phase. You had the idea, and now you want someone else to handle the execution. If only life was that easy.

It’s very, very rare to find someone to license your product just from your idea. You’re going to need a prototype and market proof that it will sell before you can even consider licensing your product.

Strategy #5 – The Co-Founder Startup Strategy

In this strategy, your first step is to search for co-founders to fill in any gaps in your own skill set. For example, if you’re really strong at sales and marketing but you have no engineering or technical skills, then I highly recommend that you find an engineer to be a co-founder.

The ideal co-founder team is probably three people for most projects. You’re going to need someone that knows the hardware, you’re going to need someone that knows the software, and you’re going to need a third person that you could call the hustler – the sales and marketing person.

The hardware co-founder role could be potentially split into two, making a total team of four. In this case, you may have an electronics engineer as one of the co-founders and then, say, a mechanical engineer or industrial designer to be the other one.

The issue with finding a co-founder is you’re asking for a huge commitment. In a lot of ways you’re essentially looking for an investor. Instead of investing money, you’re asking them to invest their time in your project and time is extremely valuable to pretty much everyone. For this reason, it can be extremely challenging to find a co-founder.

You want them to be excited and passionate about your product. You want them to believe your product will succeed, and that they want to be part of that success.

You also want to find co-founders that are in the right stage of their life. If they’re focused on their own career or startup they might not have the time or passion to devote to your project.

You need to find someone that can put a lot of mental energy into your project for free. They have to be financially stable and also have the time to commit to your project.

Since you’re asking for such a big commitment, in most cases you’re going to need to do some upfront work. You have to offer more than only your idea.

Early marketing research and any work accomplished so far will help sell them on the potential of your idea. But you have to prove that you know how to execute on the idea. You always have to bring something to the table beside your idea.

For example, if you don’t know how to design a product, then you need to become great at marketing and sales. I’m a classic technical introvert, but I’ve been able to come out of from behind my computer screen to do sales and marketing. If I can do it, I know that you can successfully leave your comfort zone too.

Look for co-founders who are compatible, but with contrasting personalities. For instance, if you’re an engineer, and you’re an introvert that’s more comfortable working in a lab or behind a computer, then I would recommend finding a co-founder that’s an extrovert who loves doing sales and marketing.

You need to be compatible yet contrasting. You don’t want someone just like you because they’re not bringing a new perspective to the table. Also keep in mind that a co-founder is like a spouse. You will be working together all the time, for years, so make sure you like each other.

Strategy #6 – The Small Company Strategy

This strategy is aimed at small, established companies that haven’t previously developed a custom product.

As an established business, you have the funding for developing the product. You’ve probably done a good amount of market research and some of the upfront work. Now, you’re ready to jump into fully developing the product.

For this strategy, we’re going to discuss two options: do you hire a full-time engineer or do you outsource the development?

First of all, most products are going to require more than one engineer to develop them. If you’re looking at hiring an engineer to develop your product, most likely, you’re going to have to hire at least two engineers.

Obviously, hiring one engineer or even two engineers full-time is exceptionally expensive. That may make sense later, once you are developing multiple products and need design engineers on a regular, ongoing basis. But for the first product, I highly discourage you from hiring a full-time engineer.

First of all, until you’ve been through the process you won’t have a good understanding of the qualifications required for the ideal engineer. Once you’ve gone through this process by outsourcing development, you’ll be in a much better position to hire full-time engineers to develop future products.

The other issue with hiring a full-time engineer is, obviously, you must make sure you have enough work to keep them busy. A benefit of outsourcing is you pay only when you need an engineer.

That’s why it’s typically best to only bring on full-time engineers once you’ve gotten past the first product and you’re planning on developing products on an ongoing basis.

Strategy #7 – The Manufacturing Partner Strategy

For this strategy, your focus is on finding a manufacturing partner that will help develop your product and scale it to manufacturing. If you’re going to try this strategy, you need to find a manufacturer that believes in your product enough to partner with you.

They’re going to be investing their money, time, and resources into your project. Therefore, most manufacturers are not going to be interested in this strategy.

Finding a manufacturer to partner with you can be a good strategy in many cases.

Similar to finding an investor or a co-founder, you’re asking for a serious commitment from a manufacturing partner. Expect that only a small percentage of manufacturers will be interested in this offer, so you will need to pursue multiple manufacturers.

Having a prototype and some solid market feedback will help prove to a manufacturer that your product is worth pursuing. An even better case is if you also have a retailer that has expressed interest in your product.

After you find a manufacturing partner, they can help finish any remaining development. You will typically be expected to handle the sales and marketing.

You have to prove to a manufacturer that you can do the sales and marketing because that’s not likely to be their strength, especially if they are located in China. You can provide value to them by having access to a new market.

A manufacturing partner is most likely going to require an exclusive manufacturing agreement, at least for a certain amount of time. They don’t want to do all this work and invest in your product and then, a few months after manufacturing starts, you decide to take your business to another manufacturer.

This is a good strategy if you don’t have a lot of capital to develop the product on your own. This is also a good strategy if you’re really good at sales and marketing and you’ve done enough upfront work to convince a manufacturer that your product is worth the risk.

NOTE: There is a company I have worked with previously who matches up startups with manufacturers in Asia that already produce similar products and that are open to working with startups. If you are a member of my Hardware Academy platform I’ll be happy to introduce you to them (sorry this is too valuable to share with everyone and I save it only for my members).

Conclusion

Developing a new electronic product and bringing it to market is a massive undertaking. In this article I’ve presented you with 7 different product development strategies. Which strategy is best for you depends on your experience, your team, and your financial position.

In some cases you may find a combination of several strategies is your best option. For example, for my own product I followed both the Engineer Strategy and the Manufacturing Partner Strategy.

Thank you so much, glad you found it helpful!

“The downside of working with freelancers is you really need technical knowledge to be able to review and judge their work.”

The other downside is that you need to establish a very clear spec for what you want the freelancer to do. This is also hard for first-timers, who are often focused on the end result and don’t have a clear picture on all the interim steps. Hard experience talking here…

Great point, as always, Dave! Thanks for sharing.

Great article John. Well thought out and the only other thing I can think of is partnerships/M&A opportunities with existing companies- Will take an impressive sales job to do so with an existing company.

Thanks John! A very in-depth article that will surely help us choosing the right decision to succeed on our new product. Thanks for your efforts!

Thank you Paul!