How to Determine If Your New Hardware Product is Really a Good Idea

In this article I’m going to answer one of the most frequently asked questions I get from entrepreneurs – is my product idea a good one?

Before you begin the long journey to bring a new product to market you need to first determine if your product is a good idea for you.

In most cases this means will a product be a huge market success. No one person can ever answer that question. Only market feedback and data can tell you that.

But, there are so many other elements to what constitutes a good idea for a new product. A big part of that question really depends on you and your team much more than it does on how good the idea itself may be.

An idea alone has no value, and the value is in the execution. This is something you will see me repeat many times in my content.

A great idea with horrible execution is what I would classify as really being a bad idea from the start. For example, I think Star Trek transporters are a great idea, but I’m pretty sure if I tried to bring that product to market I would fail on the execution of it.

What really makes a new product a good idea is one that can be realistically executed all the way to market.

In this article, I’ll break down what it means to be a good idea into several parts: the founding team, development, manufacturing, marketing, and sales.

Founding Team

I encourage everyone to think about the success of a product idea in a new way.

Ask yourself, “will I, or my team, be successful with this product”, instead of “will the product itself be successful?”

Often, the founders are more critical to the success of a start-up than the product idea. That can be really difficult for people to wrap their head around.

Remember, the value is in the execution of the idea, not the idea itself. Only you can control the execution.

Even the iPhone would have failed without effective execution of that idea. Although it takes both a good idea, and a good founder for success, don’t place too much value on the idea itself.

This is why early investors are more interested in the founders than they are the product.

Experienced investors know that everyone has ideas and many of those ideas may be good. But very few people have what it takes to turn an idea into a real product that’s developed, manufactured and sold.

Ideally, the product idea also corresponds with your areas of expertise, whether that be engineering or market experience. The more you know about the engineering needed for your product, and/or the market you will be selling into then the less risky it is for you.

Product Development

A “good” product should be relatively easy and affordable to develop. The development cost for a new hardware product can vary from tens of thousands of dollars on up to tens of millions of dollars.

There is a huge range of product development complexities to consider.

An example on the super expensive end of things, Apple reportedly spent over $150 million dollars to develop the first iPhone.

You should definitely classify a project that expensive and complex as a “bad” idea if you are a cash-strapped startup. Even a decently funded startup shouldn’t develop something this complex.

Products such as new smart phones, tablets, computers, drones, and advanced robots are going to cost too much for you to consider, unless you have major outside funding.

Trust me when I say that developing even a very simple product is super difficult. Simple doesn’t exist when it comes to bringing a new product to market.

Even the simplest of products will be a challenge to develop, manufacture and bring to market.

I believe that your best shot at successfully introducing a new product to market is to simplify your product with the Minimum Viable Product (MVP) strategy.

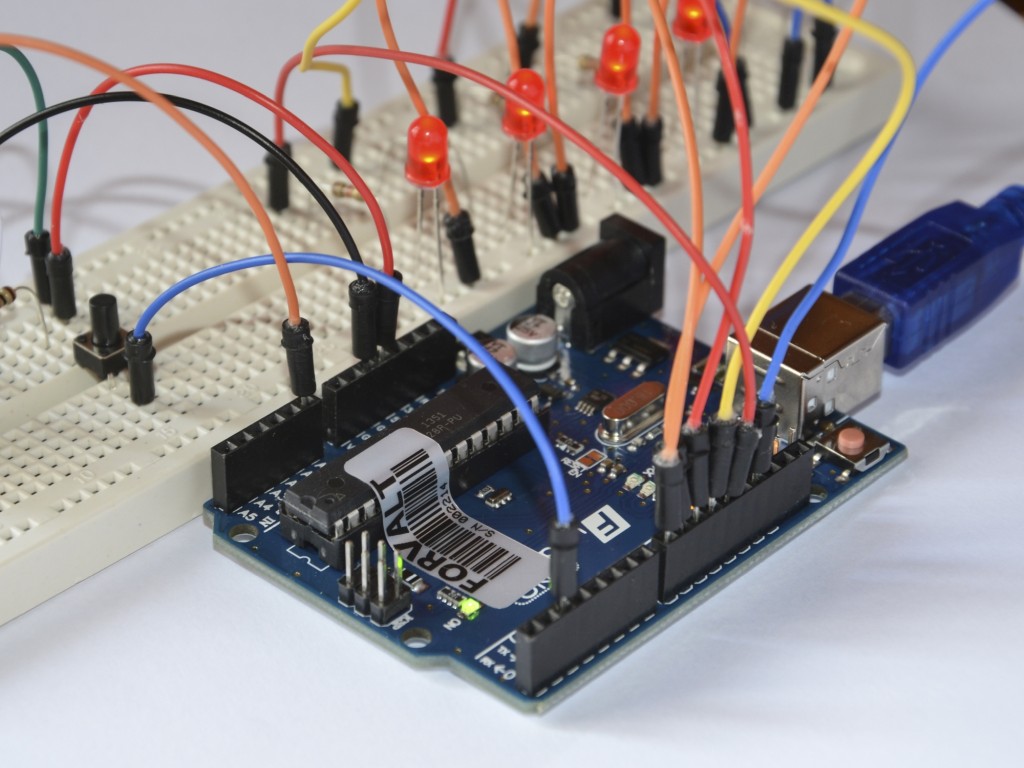

For most of the product ideas I see, the electronics and software are usually the most complex to develop. In order to reduce your development cost you should focus on minimizing the complexity of the electronics and software.

In general it is more expensive to setup manufacturing for the mechanical portion of a product, which is usually the plastic enclosure.

Manufacturing

A good product has to be feasible to manufacture. This means you must be able to actually manufacture your product in large volumes. Setting up your manufacturing has to also be fairly affordable.

Imagine a product that has a dozen unique, custom-shaped plastic parts. This type of product will have high development costs because of the number of prototyped parts it will require.

Later on, it will be very expensive to setup manufacturing in volume.

To setup up manufacturing, every piece of plastic needs its own unique injection mold. These molds are very expensive, and range in price from a few thousand dollars up to as much as tens of thousands of dollars.

If your product has 12 unique plastic pieces, your mold cost is multiplied by 12. This can be a financial obstacle to setting up your manufacturing.

This doesn’t necessarily mean that your final product won’t be affordable to manufacture. Your per unit cost may eventually allow you to sell your product for a good profit. But you do need to consider if it will be prohibitively expensive to setup the production line.

There are two costs when it comes to manufacturing: the upfront cost to setup the manufacturing process, and the actual manufacturing cost per unit.

A product with a high manufacturing setup cost may have an affordable manufacturing cost, but it will require a lot of capital to set up manufacturing.

One way to decrease manufacturing cost is to use multi-cavity injection molds. Your mold will produce more than one part at a time, which lowers your manufacturing cost.

However, multi cavity molds are much more expensive to purchase. Consider partnering with a manufacturer who is willing to amortize the setup costs. This is one way to overcome a high set up cost.

It is also easier to raise outside funding to finance manufacturing than it is to fund the development.

It is critical to ask yourself, can my product be manufactured at a cost that is low enough to generate a good profit?

In general, your retail price should be three to four times your manufacturing unit cost. Subtract your manufacturing cost from your retail price to calculate your profit margins. This will allow you to determine if your product can be manufactured and sold at a high enough profit.

Don’t forget that manufacturing costs vary greatly depending on the production quantities. For instance, your per unit cost to produce 1,000 units will be much higher than when you produce 100,000 units.

Be sure to estimate your development costs, manufacturing setup costs, and manufacturing unit costs before your begin developing your product.

Marketing

Is your product idea in an easy to reach market? Maybe you’ve heard experts recommend focusing on a niche market. There is even a common saying “the riches are in the niches”.

Is your product in a large, general market? If you think everyone could use your product, it can be hard to reach anyone in the market without spending millions on advertising.

You should focus instead on a market niche that you already understand. For example, if you are a dentist then it makes sense to focus on a dental product. If you’re a tennis pro, then focus on a fitness product.

An example of a bad target market was one of my very first entrepreneurial ideas.

My very first business venture was a product line for tourists in Australia.

This was problematic because I am not Australian and I didn’t live in Australia, or even the southern hemisphere. This made it extremely hard for me to reach my market.

Although I had some early interest from tourist shops in Australia, I quickly learned that trying to sell a product to people on the other side of the planet was a horrible strategy!

Making things worse, I didn’t have any experience with the tourism industry especially in far away locations like Australia.

Ideally, your target market will exist locally, so you can start there before expanding to outside markets. Starting small and local, allows you to learn about your market and product, and to pivot when necessary.

Lastly, ask yourself if your product is differentiated from the competition? You want a unique product, but not one that is so novel that it confuses potential customers.

A good product idea shouldn’t be so out-of-the-box that customers need inordinate amounts of education before becoming potential customers.

If your product is so new, potential customers may not realize they need it. Then you have to go through the extra step of educating them about the problem your product solves. This makes sales a lot more challenging.

Sales

Asking if a product idea is “good” is really asking, will my product sell well? I cannot honestly answer whether or not your product will be a sales success.

In fact, don’t trust anyone that confidently tells you your product will sell well. Chances are they are trying to scam you or they don’t want to hurt your feelings.

Anyone who knows what they are talking about, knows that the opinion of one person is meaningless.

No one person can know whether or not a new product will be a sales success. Even people with tons of experience in consumer products don’t know for sure if a new product will sell well.

You may think that a merchandise buyer for a company like Best Buy, for example, will know how a product will sell. Even with lots of data on prior products, they won’t know for sure.

This is why big retailers always start with small test orders. When I was a designer for Texas Instruments I learned that about 80% of their revenue came from only 20% of their products. Only a handful of their products were super successful.

Fortunately for my career, several of the products I designed for TI were very successful and they make the company millions of dollars annually.

But there is only one way for even large companies like Texas Instruments to know if a product will sell well and that is to test it on the market.

The key thing to remember is that no one knows ahead of time if a product will sell. This is why you need to start off with small orders. Don’t ramp up production until you have proven sales.

One of the primary complexities when bringing a product to market is you don’t know for sure if it will sell until you try to sell it.

Fortunately, with crowdfunding, you can get early sales proof about your product.

With crowdfunding, you only have to get to the prototype stage to pre-sell your product through a campaign. The money you get from the campaign is real sales proof.

This is the best you can do before actually having a product manufactured and on the market.

You don’t absolutely need a fully developed prototype in order to get crowdfunding, but in most cases it is best to have one.

Otherwise, there are so many unknowns that it is nearly impossible to forecast accurately when the product will be ready to ship.

Ultimately, no one person’s opinion about your product matters unless they are willing to put their money where their mouth is.

Summary

I can tell you if your product is a good idea in regards to development, manufacturing, and perhaps marketing. But I can’t know if your product will actually sell well. No one really can.

The only way to truly know if a product will sell well is by selling it. Regardless of how great you think your product is, or how many people tell you it’s a great idea, remember that only a sales test can answer this question.

You need to be confident in your idea, but overconfidence without proven sales can lead you down the wrong path.

Once you have proven sales, you can then confidently focus on scaling up production.

this blog will surely help a lot of startups, i am also doing similar to this by providing wireless nurse call system for senior care. click my profile for more info