How to Make Fast Progress on Your Hardware Project with Miguel Hernandez (Founder of Palocam)

Miguel Hernandez is the co-founder of Palocam, which manufactures a pole-climbing camera for recording sporting events from above. The following is a conversation between John Teel and Miguel where they discuss everything from product development to crowdfunding.

JOHN: Just to start – can you give me a little bit of background about yourself and how you got to where you are now?

MIGUEL: I am the cofounder of Palocam, and I’m originally from Spain. I’ve been living in Canada for 26 years and me and my father, who is now a retired electrical engineer, came up with a product idea.

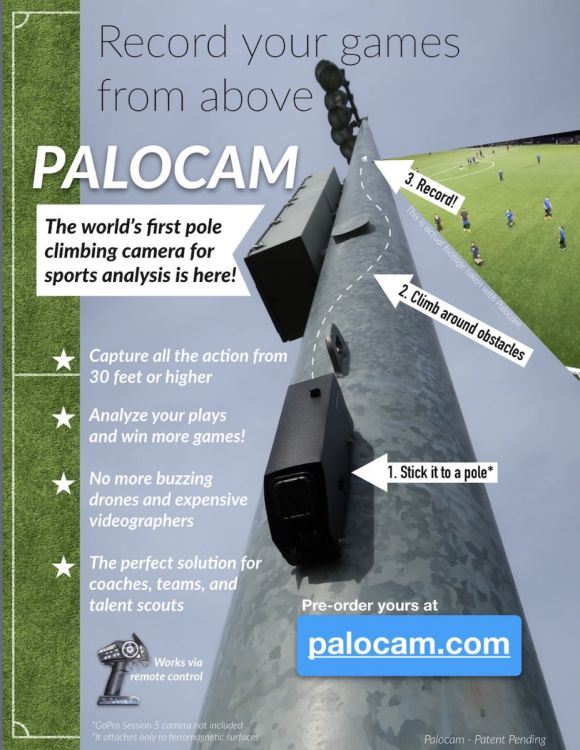

It is basically a device that can climb metallic poles – poles that you see around a typical soccer field – and you can drive this device, with a camera attached, up 30-35 feet.

From there you can record your soccer games (in my case it’s soccer because that’s the sport I play, but it could be any other type of sport) from a high vantage point, which allows you to get a really nice, bird’s-eye view of your entire game.

Then, you can use that for analyzing your game and improving your strategy. It is basically a very affordable way to beautifully record your game, something that is traditionally only achieved using a drone.

The problem with drones is that they have low autonomy (like 30 minutes flying time) and you often need a permit to even fly. Or, you would have to hire a videographer with a big, chunky, cumbersome tripod.

My product is something that you just put on a pole near the game field, and then you remotely drive it vertically. You can steer around any objects too.

Then, you leave it at the desired location, about 30 feet up. You can press record, and go about playing your game. An hour or two later, when you’re done, you drive it down the pole, and you now have beautiful footage of your entire game. That is the product in a nutshell.

There’s really no other alternative on the market, right? I’ve never seen anything like your product before.

I did some research, and didn’t find anything like that. I have a mechanical engineering background, and I did a prototype made out of Lego technics. I put it together in about a couple of days, put a magnet on the bottom, and it worked!

Is Palocam mainly for video, or are you also set up to do audio recording?

If you put a GoPro camera on the Palocam, the camera will also record audio. When I record my own games, you can hear very well what’s going on. So if you were to have fans around, you could hear the fans cheering and all of that, which would add another dimension to the entire recording.

Has your dad been involved with the project from the very beginning?

I came up with the idea first, since I’m a soccer player (my dad doesn’t play soccer). I created the initial version out of Lego. I actually scavenged some parts from a remote control truck that I had, and I just put it together with the Lego.

And then I thought that if I want to sell these, I probably need to do something more robust than Lego. And that’s when I talked to my dad and told him that I came up with this idea.

My dad has over 40 years of experience in automation and electrical design, and he’s probably a genius when it comes down to all of this. I don’t have any understanding of how to build PCB boards (printed circuit boards) or do firmware and all of that.

But my dad, that’s his area of expertise. So he said he would help me. It took a long time with many iterations, but we were able to design the prototype that we now sell from our website.

So you’ve made the major breakthrough of actually selling units, so a big congratulations on that! Can you tell me about that?

Yes, I sold two on Sunday to the same guy! He was so excited because I only had two units left – we put them together by hand, so we only have so many in stock – and he said “I want to buy those two before anybody buys them!” In fact, actually, we’re going to ship them tomorrow.

How did you find him, or how did he find you?

About 99% of the traffic comes through our YouTube channel. I made a YouTube channel where I posted how the Palocam works and some videos of me playing soccer and recording myself with Palocam.

I got about 10,000 views from that, and some of those views were interested in learning more about the product. So they end up on the website, and then some people inquire about the Palocam and some people end up buying it. He found me the same way.

You’ve been extremely open in the Hardware Academy community. You’ve shared all the financial data for your project including: how much money you’ve invested, how much you sold the units for, and how much money you’ve lost on those initial units.

You are really open with a lot of data, which I think is great, and anyone who reads my blog knows I’m a big proponent of being open and not so secretive.

Can you walk through all the progress you made before you joined the academy?

I think the idea is under two years old. I came up with the idea, and within two weeks I had the Lego prototype, and it was working. I failed at some other startups, and the first thing you want to do that I hadn’t done with other startups in the past is to validate the idea as soon as possible. And the ultimate validation is finding paying customers.

Everybody’s going to tell you they love the idea, but you want them to open their wallets, and that’s the ultimate validation. I wanted to do that, but the problem was that I had a Lego prototype, and I felt bad selling Lego.

And I probably should have started selling the Lego version because literally two weeks after I finished the Lego version, I applied to Y Combinator, which is probably one of the top, if not the top, startup incubator in the world.

They have clients like Dropbox and Airbnb and stuff like that, and they also have a hardware section that is run now by the co-founder of Pebble.

Pebble’s co-founder is Eric Migicovsky. He had the biggest to date Kickstarter campaign with over 20 million dollars. And literally two weeks after finishing the Lego prototype, I applied to Y Combinator and to my surprise, they flew me to San Francisco.

I had an interview with Eric Migicovsky and two other partners talking about the possibility of investing in this idea that was basically a Lego prototype.

That’s amazing! So only two weeks after this idea you had a meeting with the co-founder of Pebble at Y Combinator?

For people that are not familiar with how Y Combinator interviews companies, they usually interview between 800 to 1,000 companies for every batch, and they have two batches every year.

They go very fast. These interviews are about 10 minutes long, and they drill you. There’s no time for you to pitch or memorize anything. They’re very smart people. They have sold companies for millions, and you have to be on your feet.

And so I prepared as much as I could to answer all potential questions except the most important one, it turned out.

The first thing that Eric Migicovsky asked me, he looks at the product, he said “ok, that looks good. How many have you sold?” And I was like, “zero.”

He asked, “why haven’t you sold any?” And I said, “because it’s just a Lego prototype.”

“How do you know people want this?” he asked, and I replied, “I just finished this one. Give me some time.”

And he told me, “I think this is a great idea. Come back when you’ve sold a few.” And then I’m thinking, why did you fly me here to ask me this question?

You can tell this is someone with experience because he asked a brilliant question, but why didn’t he ask before he flew you down there?

I think they want to meet founders in person because a lot of these savvy investors invest in the person more than in the product itself. They want to see if you have what it takes to execute.

Coming up with a Lego prototype is not that difficult, the difficult part right now is bringing that product to the market and to mass produce it. That is like 99.99 percent of the effort.

I think they just wanted to get an idea of who I was and the potential of the product. And then, obviously, the big question is how do you intend to sell them?

Obviously, they didn’t invest, which is ok. I was not expecting, first of all, to have this opportunity that early on.

Honestly, that would’ve been too good and too fast! You would have probably become overly confident if you got an investment only two weeks after having the idea.

And by the way, I’ve applied to Y Combinator like seven times before with other ideas and this is the first time I got flown in. All the other ideas got shut down and I didn’t even get an interview.

It’s validation for you. It’s not validation with people giving you money to buy the product, but it’s validation from people that know what to look for in a successful product.

I was super excited, and they didn’t invest a hundred and fifty thousand dollars, which would have been super useful, but at the same time gave me validation.

And then I came back and that’s when I involved my dad in the project. And I said, let’s build this into something that looks like an actual working prototype that we would be proud of selling from our website.

And that took a long time, and I had to get a 3D printer. I had to learn how to model in Fusion 360, and then my dad started doing the schematics and all of that.

And it took a thousand hours probably of work trying to iterate and learn and coming up with 16 different versions. But eventually we put it on the website, and I got my first sale, and it’s been a slow selling process.

One of the things that I think slowed down the sales is that COVID came. And of course, a lot of the leagues, including my soccer leagues, closed. That’s when sales slowed down, and we’ve only had 12 sales in a year and a half or something.

I’m an engineer at heart, but being an entrepreneur for about 15 years or so has taught me that it’s all about marketing and sales.

I’m lucky in a sense, because I’ve been running an animation studio for startups for 10 years, so I understand a little bit what it takes to produce explainer videos and do marketing ideas with video.

That gave me that advantage. And that’s why I would say most of the sales have come from my ability to create videos and explain things in a simple way.

Just to get to the point where I joined the Hardware Academy, sales slowed down, and so I lost a little bit of interest. Plus, we were losing money on every sale, which is something that most hardware entrepreneurs probably know when people do this for the first time.

And, I’m like, ok, it takes 10 hours to put this product together. We’re losing money on each sale. If somebody orders 100 Palocams, we’re going to be tied up for the next two months to lose a bunch of money. So I put the project in the freezer for a while.

And then things started opening up about two months ago, and I start getting almost every other day somebody inquiring about Palocam. It seems that people are finding me organically, that there’s an interest.

I say, ok, let me try again, see what it takes to mass produce this because we cannot do this by hand. And my dad is doing most of the assembly work, and I’m like, I don’t want him to be tied up doing something that is extremely painful to do, putting together a product that takes 10 hours.

That’s when I joined The Academy, and I started asking questions about how I could simplify the product, how can I contact manufacturers in China, how can I write contracts, a thousand questions. And I’ve been able to get a lot of those questions answered in your Academy.

When you first came in the Academy your product had 18 custom molded plastic parts, and I believe you’ve reduced that through some redesign. How many custom parts have you gotten that down to?

Based on the feedback I got, ideally, you simplify the product because the injection molding is one of the most expensive parts for producing the product. And if you have many parts, that means you’re going to have several molds, and each mold could be up to $50 ,000 or $100,000 per mold.

So even if you use family molds, I still would need two to four molds, which means I have to spend at least $200,000 on molds.

So I had to get creative, which made for a very interesting challenge. How do you make something complex into something simple? I love that type of a challenge. Right now, I think there’s only going to be two or three parts!

Wow, that is some serious simplification to go from 18 custom parts to only about three parts!

We actually already built a prototype of the simplified version, which we could sell at a profit, and it would take maybe two or three hours to put together.

So your assembly time went from 10 hours to two or three hours, and you can sell at a profit versus a loss! Was there any reduction in functionality?

It’s actually better. Instead of one motor it has two, so it has double the torque. It can carry double the weight and you can put bigger cameras on it. The only limitation is it no longer has the ability to pan and tilt, but we’re thinking we could sell that separately.

Getting rid of the pan and tilt function got rid of a lot of complexity. And we can consider selling a separate version that comes with those features, and charge extra for it.

But that would be in the future. Right now, I want to see if we can sell the simplified version because that would make our life so much easier.

What are your plans in regards to crowdfunding? You’re getting to a really good stage where I think crowdfunding can solve two problems at once – you get money, and you get customers, and you get validation. Are you looking into doing any type of crowdfunding for this?

Of course, I’ve thought about it almost from day one. I think anybody that comes with a physical product idea, the next thing is like, “oh, I just want to kickstart it.”

Most people want to do that immediately. You’ve been wise, you don’t want to do it from day one, but you’re getting to where I think it becomes more feasible now.

I thought about it, but then my biggest question is what if I’m successful? For those that are familiar with the Pebble story, although they were the most successful kickstarter campaign in the world, with several campaigns with over several millions of dollars raised, that didn’t work out so well because they were overwhelmed with their success.

That’s one thing. And then they had a lot of issues with coming up and manufacturing a product at that scale that fast. Sometimes success can be tricky to deal with.

Also, as entrepreneurs, we’re impatient. We want to go from zero to a million now, but that level of hyper growth just creates a whole set of new issues that you have to deal with. I think it’s much better to do slow and steady growth instead of being an overnight success.

I was looking at which platform would be better to run a kickstarter campaign, Indiegogo or Kickstarter.

Indiegogo seems to be maybe more suitable for this type of electronic consumer product. So I was looking at creating an account last week but it’s a long process.

And you mentioned this, and you’re 100 percent correct. You cannot expect to run a crowdfunding campaign and just have people find it. You have to build the audience first.

This is something that can take months or even years of building an email list, or producing marketing materials, or building an audience of very excited early backers that believe in the product.

So when you launch, you’re not launching to the void, hoping for sales. I don’t have that big email list yet. I have a few subscribers on YouTube, so I know if I were to launch tomorrow, I wouldn’t get that many sales because I don’t have that big of an audience.

The strategy I like is not going quite so big, like Pebble, trying to raise millions of dollars, because then all that does is just put all this pressure on you, and it’s too much money and too fast. And most people aren’t prepared to all of a sudden have millions of dollars to spend. They go a little bit crazy.

That’s a good point because Pebble is just an outlier. But, a lot of projects that you see on Kickstarter or Indiegogo, they’ve launched maybe two or three times in the past. So if you fail on your first launch, it’s not the end of the world.

You can refine the product, listen to customer feedback, and then launch again with a bigger audience. So that’s probably a good strategy, an incremental increase of crowdfunding.

Everybody thinks money is going to solve all their problems. I think everybody thinks that in life in general, but especially when you’re doing a startup. It takes money, there’s no doubt about it. You’ve got to have some money, but I find having two much money encourages founders to take risky shortcuts.

The money should come from people that actually really believe in the product. Getting money from an investor doesn’t mean your product is going to sell. Being wealthy individually doesn’t mean your product is solving a real problem.

Crowdfunding, I think, is the closest thing to getting validation because it’s people that believe in the product and that want to own it. But again, if you’re very successful, that could be a problem in itself because now you have to fulfill all these orders.

And one of the reasons why I didn’t want to run a campaign early on is because what if I sell a thousand copies, then I’m going to have to figure out how I make them, and it takes me 10 hours to make each one.

Then multiplying a thousand by 10, we’re talking 10,000 hours of work!

So that’s why I wanted to figure out how I could get to a situation where I have that ready. I know what it’s going to take. I need to have a manufacturer in place so that if I get a bunch of orders, they can fulfill them for me, not relying on me manually building them.

Fairly soon after joining the Hardware Academy you got an offer from another member to either partner on your project and he even expressed interest in investing in your project. Can you tell me more about that?

I joined your Hardware Academy almost two months ago. And by the way, I am very happy with this. I think you’ve done a great job curating a lot of great experts.

Any questions that I have get answered within 24 hours by people that are highly qualified, and they actually take the time to answer really long questions with really long answers. That’s pretty amazing, and I’m totally getting my value for it.

For anybody that’s starting out, I think you want to find experts and peers and people that believe in your product as soon as possible.

Another thing I would suggest is that a lot of people are very wary about sharing details about their product because they think someone is going to copy their idea. But, I’ve been able to connect with a few of the members in the academy, and there’s a private messaging option.

I got a private message, and one of the members is building his own product, and he mentioned at the end of the message that if I was interested in somebody investing in this idea, that he was interested.

So we got on a call immediately. And then towards the end of the call, he did mention that he would be interested in potentially investing. We’re just talking right now.

That’s the best kind, the kind of money you don’t even ask for. You know you are doing something right when the money wants to come to you instead of you having to search it out.

Yes, that was again a great validation. So even if nothing happens to me, that’s another point of data that says, “okay, I’m moving in the right direction.”

You take advice and you implement it really quickly. I suspect he saw that and knew you were someone that can actually execute on an idea. And that’s the kind of stuff investors love.

I’m very happy to have somebody believe in this product and me and my dad, because it’s a very challenging thing to build a product from scratch.

Having that support from the Hardware Academy community, from people that believe in you, people that are even willing to put money in your product, it really keeps you going.

You should add radio so you can stream live. But, I’m sure you have already thought of that!

Great interview – congrats on all your success! Who is the Chinese manufacturing company – need to contact them!

That’s inspiring, Thanks for sharing guys