Why You Should Begin With a Preliminary Production Design for Your Product

Define your product, design it, then manufacture it. Right? Well, not exactly. Although, this is the process most entrepreneurs follow, it’s not the process you should follow.

Before you jump head first into fully designing your product you really need to look at the big picture. This will allow you to answer many questions earlier than otherwise.

The best way to achieve this early insight is by inserting an intermediate step between defining your product and fully designing it. This intermediate step is a preliminary production design which I will also sometimes simply call a pre-design.

By preliminary production design I mean to design the product with just enough detail to answer some important questions. But without worrying yet about the tiny details that don’t have a big impact.

The problem is that once you dig into the full design you tend to get buried in the technical details. The old saying you can’t see the forest through the trees definitely rings true in this situation. To be a successful founder you need to see both the trees and the forest!

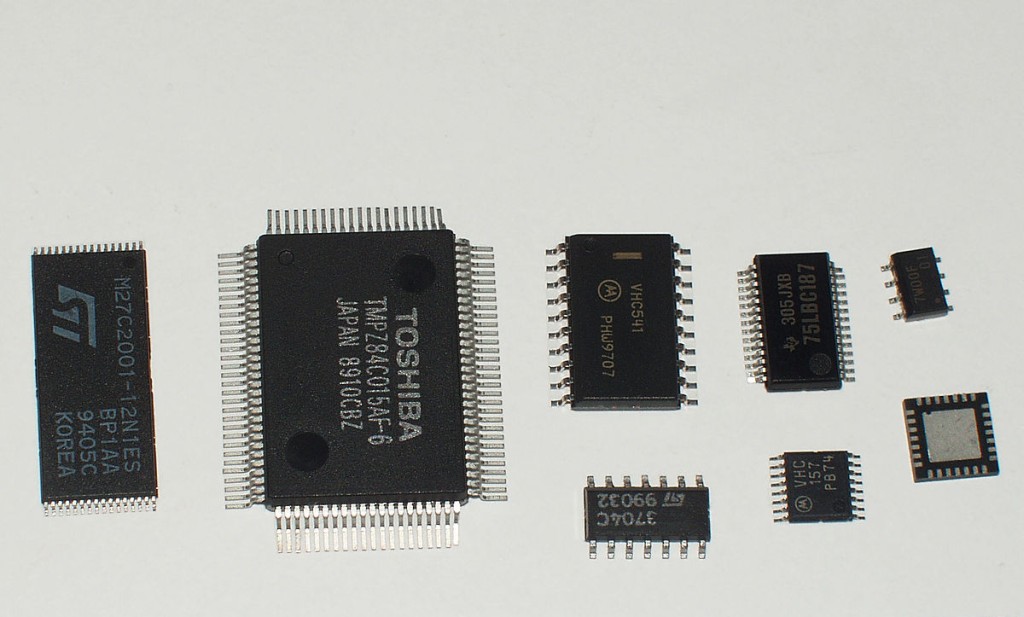

For example, with electronics design most of the cost and functional impact is related to the microchips (integrated circuits – ICs). The secondary components, such as resistors and capacitors, don’t really matter that much. Their cost is usually negligible once you reach manufacturing volumes.

The exact specifics of how all of the various electronic components connect together also doesn’t really matter at this early stage. Sure, you need to define in broad terms how the components will interface, but you don’t need to worry about the small details yet.

For example, if a sensor connects to a microcontroller you should define the interface as being I2C (a 2-wire serial protocol common with sensors). But, at the pre-design stage you don’t need to worry about details like the pin numbers or the value of the required pull-up resistors.

When designing a new product most of the work is in the details. But in most cases those details don’t really have much of an impact on the big picture.

For a typical product here are the steps I perform as part of the preliminary production design stage:

1) Identify each core function such as the microcontroller, Bluetooth, sensors, power management, etc.

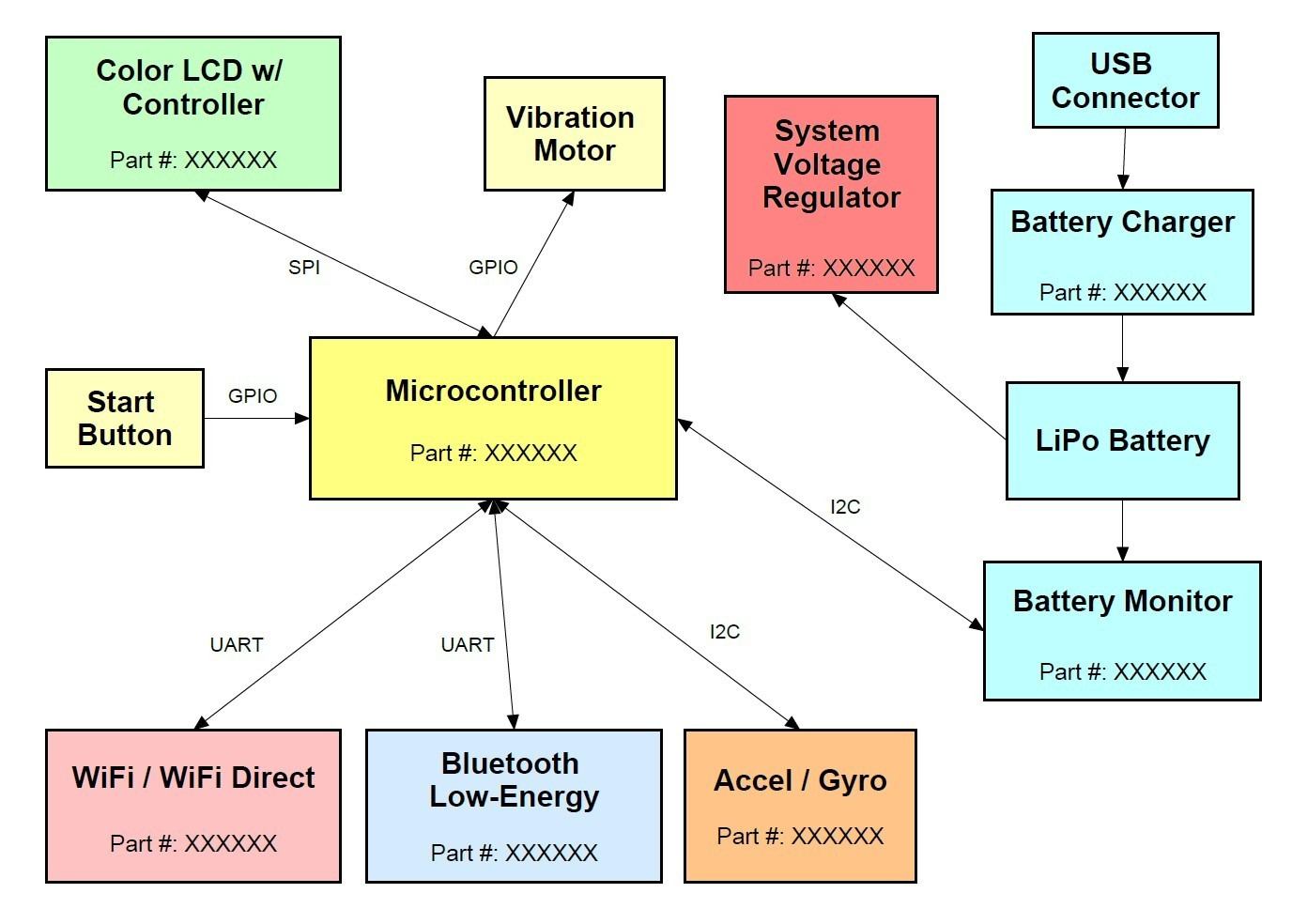

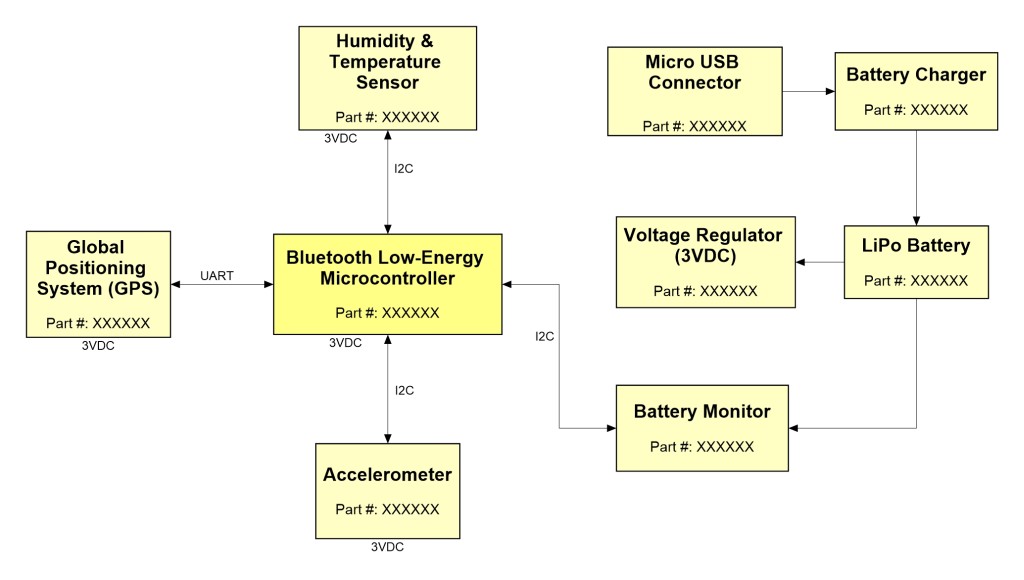

2) Create a block diagram showing how to incorporate all of these core functions.

Figure 1 – Example of a block diagram

3) Define how the components will be interconnected by specifying UART, I2C, SPI, I2S, GPIO, AIO, USB, MIPI, etc. Don’t worry if you have no idea what these acronyms mean. Just know that specifying them in the block diagram is critical to selecting the right electronic components, especially the microcontroller or microprocessor (the “brains” for your product).

4) Select the best microchips to perform the various product functions. This is the most important step of the preliminary production design. Lots of things need to be taken into account when selecting the critical components such as performance, cost, availability, manufacturer support, packaging, physical size, and the forecasted End-of-Life (EOL).

Figure 2 – Various examples of electronic microchips (integrated circuits).

5) Estimate the size of the Printed Circuit Board (PCB) required and the number of layers needed. This helps to determine the minimum required size for your product, as well as the manufacturing cost of the PCB.

6) Estimate the number of BOM components, number of PCB pads, whether components will be soldered on both sides of the PCB, etc. These are all details that will allow you to eventually estimate the cost to manufacture your product (more on that in a bit).

7) Determine the number, size, and general shape of any custom shaped plastic pieces required for the enclosure. This information allows you to estimate the cost for the injection molds that will be required to scale from prototype to mass manufacturing. It will also allow you to estimate the manufacturing cost for your enclosure.

8) Ascertain the complexity of final assembly for the product. Are there lots of pieces that all have to squeeze into a tiny enclosure very carefully? If so, this will impact the cost to assemble the product. Ideally, you can estimate how long it should take to assemble your product.

9) Finally, give some thought to how complex it will be to test your product during manufacturing? Ideally try to estimate how long it will take to properly test it. How long this takes will impact the manufacturing cost.

Can your product even be realistically developed? How much will it cost to develop and scale? How much profit can you make? What distribution strategy should you pursue? How much should you sell the product?

These are just some of the questions that a preliminary production design can help you answer before you actually begin fully designing the product.

Pre-designing your product before you start on the full design has many advantages. Let’s now discuss some of these advantages.

See the big picture

As I said, most entrepreneurs focus solely on the product they are developing. But remember, you’re not developing a new product, you’re developing a new company!

Repeat after me, “I’m creating a company, not just a product”. Any time you find yourself absorbed in the details of development remind yourself of this fact.

[clickToTweet tweet=”Entrepreneurs: You are not developing a new product. You are developing a new company!” quote=”Entrepreneurs: You are not developing a new product. You are developing a new company!”] Unless you’re one of the rare few who can license out their product, you won’t ever get rich creating a new product. If you want to truly get rich you have to focus your efforts on creating a successful company, not just a successful product.The more technical you are the more likely you are to over focus on the development details too early. This is because technical entrepreneurs tend to put 100% of their focus on product development. Development is what they are most comfortable doing. They have the mindset that they’ll worry about all the other stuff (costs, marketing, sales, etc.) once they get through product development.

If you are focusing solely on development then you’re acting as an engineer, not a founder/entrepreneur. As a founder you have to wear lots of hats, not just those in your comfort zone. Pre-designing your product helps you to better see all the other aspects of launching a new product (and company).

Identify key development challenges

The earlier you identify your key development challenges the better. The worst case strategy that I’ve seen is to focus first on developing the easy parts of the product. In fact, you should do just the opposite. Focus first on solving the most challenging parts of your product.

Performing a preliminary production design before you get lost in the fine details of product design allows you to more easily identify the parts of your product that will be the most challenging.

Once you do identify the critical challenges you should come up with the solution before you proceed beyond the pre-design stage. Pre-design is really all about identifying the best solutions without worrying about the non-critical details.

A preliminary production design is a top-down approach to product design. You start at a high-level and then work your way down to lower levels as needed. This is in contrast to a bottom-up design strategy where you start by fully designing each sub-function, and then eventually connect them all together into a whole system.

Entrepreneurs tend to follow the bottom-up approach, whereas established companies developing new products usually will implement a top-down approach.

The top-down approach allows for more structured control of a project which usually leads to minimized costs. This is why most companies that regularly develop new products typically follow a top-down approach.

You will save money and be more successful if you follow the top-down approach. To succeed with product development you need a structured process.

Accurately estimate of all costs

An important benefit of pre-designing your product is that it allows you to accurately estimate all of the costs to launch your product. This includes the cost to fully develop and prototype it, the cost to scale it from prototype to mass manufacturing, and most importantly the actual cost per unit to manufacture it.

Although it’s possible to estimate the development cost for a new product without a preliminary production design, your estimate will be much more accurate if you have a pre-design. The same is true with scaling costs.

However, in order to estimate the manufacturing cost a preliminary production design is absolutely necessary. In fact, this is one of the most important reasons to pre-design a product.

Most entrepreneurs, makers, and even engineers spend months or years designing their product. Once they finally have a perfect prototype then they’ll calculate the manufacturing cost. But by then you have little flexibility to control the manufacturing cost, unless you go back and do a redesign.

Knowing the cost to manufacture your product, also called the Cost of Goods Sold (COGS) is probably the most important number you should know. After all, the manufacturing cost determines both your sales price and your profit.

Remember you’re developing a company, not a product. And nothing is more important for a company than profit!

Select the best feature set

Having a preliminary production design, and accurate manufacturing cost estimates, allows you to individually price out each feature of your product. By knowing the additional manufacturing cost for each feature you can then select the most economically optimal set of features for your product.

For example, perhaps you are debating if you should incorporate GPS tracking in your product. Your market research shows that GPS can increase your sales price by $20.

But once you price out this feature you realize it will add $15 to your manufacturing cost. Based on this data you may then decide it doesn’t make sense to add GPS because the profit margin is too low for that feature.

Determine best distribution strategy

Determining the best distribution strategy for your product depends on many variables but it especially depends on the manufacturing cost, or more accurately the profit margin. As your manufacturing volume increases your manufacturing cost will decrease and your profit margin will increase.

Because of this fact, your distribution strategy may vary depending on your manufacturing volume. For example, when manufacturing volumes are low your manufacturing cost will be high.

Selling your product directly to consumers is likely your best distribution strategy in this scenario. Selling direct to consumers will maximize your profit margin. The most popular way to do this is to sell your product on your website, or perhaps through Amazon.

Later, as your manufacturing volumes increase and your manufacturing cost decreases, you will have the profit margins necessary for selling via retail outlets. Selling through retail outlets means there are more people taking a piece of the pie. This necessitates lowering the manufacturing cost in order to make this distribution strategy profitable.

Plan a better strategy to market

Until you understand the key developmental challenges, as well as the costs to develop, scale, and manufacture your product it will be impossible to plan the best strategy.

For example, without knowing your development and scaling costs you’ll have no idea how much capital will be needed to get your product to market. Without this information you’re likely to run out of money before your product reaches the market.

Early feedback from developers and customers

Incorporating a pre-design stage into your development process gives you an opportunity to get early feedback from developers, manufacturers, and even potential customers.

To get this feedback it’s best if you have more than just an idea. You should show some upfront work to support your product idea. Sure, a preliminary production design is still just an idea, but it’s an idea with some serious development behind it. Because of this a pre-design can be useful for gathering feedback.

Reduce your manufacturing cost

By putting more focus on costs early in the development process, you’ll have more opportunities to lower these costs. A preliminary production design allows more thought toward selecting the best priced components.

This is in contrast to the typical process of designing the product then later calculating the manufacturing cost. Following that process will give you very little flexibility to control your product’s manufacturing cost.

Minimize your scaling costs

Starting with a preliminary production design allows you to make better decisions that can help reduce the costs to scale your product from prototyping to mass manufacturing.

For example, one important element of a preliminary production design is to determine how many custom shaped pieces of plastic will be required for the enclosure. Minimizing the number of plastic pieces you can have a drastic impact on reducing your scaling costs.

This is because each custom piece of plastic requires its own expensive injection mold. These mold costs are one of the most expensive obstacles you’ll face taking your product to market.

Creates early opportunity to raise outside funding

You definitely need more than just an idea to get others interested in investing in your product. The idea is the easy part. Almost everyone has new product ideas but very, very few have the determination to bring it to market.

The first piece of information you need in order to raise money is how much money you need. If you don’t raise enough you’ll run out before you make it to market. Trying to raise more than really needed will present an unnecessarily difficult challenge.

Having a preliminary production design and solid estimates on all of the costs required is essential to raising early capital. Investors want to see some solid research and development to back up your product. A production-quality prototype is ideal, but many entrepreneurs have to raise outside capital before they can afford to produce a high-quality prototype.

Final thoughts

As an entrepreneur myself I completely understand how excited you are to bring your product idea to reality. This excitement is necessary for you to be able to surpass all of the obstacles in your path to market.

But, this excitement can also lead you to rush getting your product on the market. Time to market can be critical but you also need to take the necessary steps to ensure that you are proceeding down the right path.

You don’t want to ever be in the position of discovering that you’ve hurried up and developed the wrong product, or developed a product that you can’t manufacture and sell at a profit.

One of the best ways to prevent this scenario is to first create a high-level preliminary production design of your product. Starting with a pre-design will give you enough information to see the forest before you get lost in the trees.

This article doesn’t mention rechargeable batteries. Based on the prices I see, it looks like it makes more sense to source batteries from Alibaba than from Mouser or Digi-Key. And same for the RTL8710. Is there any reason I should buy these from local sources? My initial customer is a small market, but in later stages, the company would expand to bigger markets.

The reason you might not want to buy from Alibaba is the quality. You aren’t guaranteed that the battery will comply with its specs: low capacity, low C rate, safety problems (we all know what happened to the Samsung Note 7). As for chips, they might be fakes or clones that, again, do not comply with the specs, or have fewer commands available. As for the RTL8710, you might want to use an Espressif chip instead (like the new ESP8089), if that helps.