How Much Does It Cost to Develop and Manufacture a New Electronic Product?

Discover the cost to develop your product, the cost to scale up manufacturing for mass production, and finally the actual cost per unit to manufacture it.

So you have a great idea for a new electronic product? Congratulations, and I know how exciting it can be when inspiration hits you!

But before you begin spending large sums of money to get your idea developed or patented, I’d suggest you first focus considerable effort on estimating how much it will cost to develop the product.

And, perhaps even more importantly, you need to estimate how much it will cost to manufacture the product in mass production.

Don’t make the fatal mistake of underestimating these costs, or worse yet not estimating them at all, because in order to succeed to market it’s necessary to know these costs upfront.

What is the Cost to Develop a New Electronic Product?

Development costs for most hardware products are broken down into three categories: the electronics (including programming), the plastic and other mechanical parts, and the retail package.

The electronics does all of the magic, the plastic and mechanical parts hold the product together, and the retail package protects and sells the product.

For more details on how to develop a new electronic product see my Ultimate Guide – How to Develop a New Electronic Hardware Product.

Electronics and software

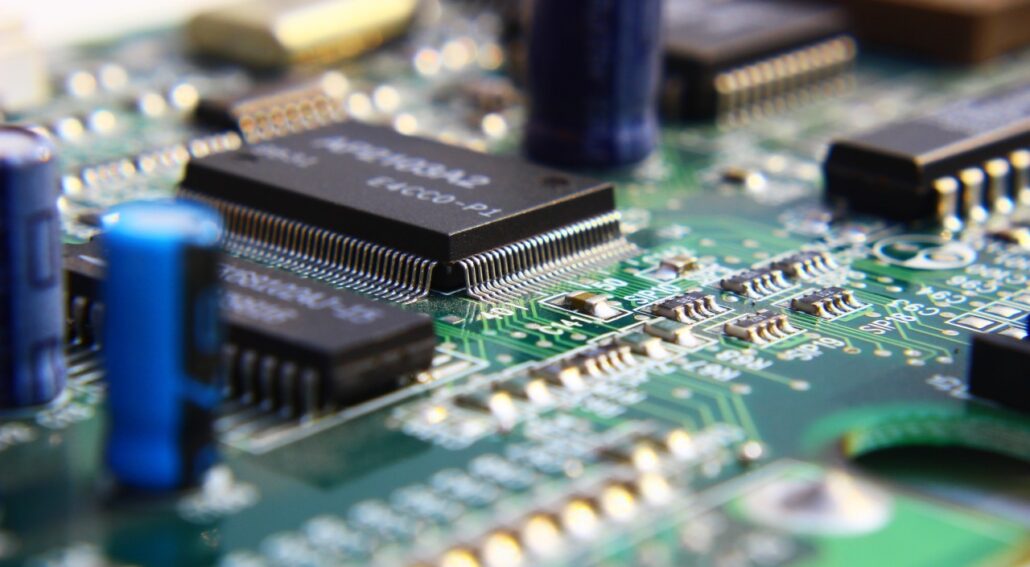

The electronics will usually be the most complex and expensive part of your product to develop. It will usually consist of two major parts: PCB design and programming since most products require some level of programming.

Unless you do all of your own product design, your development costs will be a significant expense.

Prototyping the electronics is divided into two steps: production of the blank Printed Circuit Board (PCB) and soldering of all the electronic components onto the PCB. The PCB is what holds and connects all of the individual electronic components.

How much of the development cost is for the electronics PCB design versus the software varies depending on the product. For lots of products it’s a pretty equal split between the two.

But many products can swing either toward being more hardware-complex or software-complex and the costs will follow accordingly.

I usually recommend starting off with about 3 to 5 boards, then potentially increasing the quantity for each iteration.

Once you’ve confirmed functionality and worked out most of the major bugs then you can increase the prototype quantity and begin sharing samples with investors and potential customers.

To learn more about PCB design be sure to watch this free tutorial and check out this in-depth paid course which teaches you every step of PCB design.

Enclosure and mechanical parts

Unless your product will be marketed strictly to the DIY/maker market it will require some type of enclosure, which is usually made of plastic.

You can expect to spend at least several thousand dollars to develop the 3D models for the enclosure. If appearance and ergonomics are critical for your product then the cost to design the 3D model will be higher.

Nearly all electronic hardware products require a case or enclosure.

Here’s an introductory course on 3D modeling using Fusion 360.

Some products may require additional mechanical parts such as stamped metal components, or perhaps even moving parts. This will add additional costs for mechanical engineering and prototyping.

Prototyping of the plastic enclosure is most commonly done using 3D printing technology. 3D printing builds a custom shaped part by stacking layers of molten plastic.

The popularity of 3D printing has really helped to bring down the cost of creating plastic prototypes. For some startups purchasing your own 3D printer may be the most cost effective strategy.

For a few products a technology called CNC machining may be a better choice than 3D printing. Unlike 3D printing which is considered an additive process, CNC machining is a subtractive process.

Instead of stacking layers, as with 3D printing, CNC machining is similar to sculpting. The process starts with a solid block of plastic and material is removed to form the final shape.

The main advantage of CNC machining is it allows the use of production injection-molded plastic whereas 3D printing uses special prototyping plastics that may have a different look, feel, and strength, compared to the production (injection molded) plastic that will ultimately be used.

My own product required several precise snap fits so it was critical to use the same plastic as used for production. So in my case CNC machining was the better choice. However, for the majority of products 3D printing will be the better technology.

One word of caution when it comes to plastic, what can be prototyped can’t necessarily be manufactured. This is especially true with 3D printing. With 3D printing there are few limitations on the shapes that can be created.

However, with production injection molding technology there are complex limitations on the shapes that can be produced.

So make sure you hire a 3D model designer that understands injection molding. Otherwise you may find yourself with a prototype that can’t be manufactured in volume without a massive redesign.

To learn more about injection molding see this blog and check out this paid course.

Retail package development

Many hardware entrepreneurs neglect the importance of developing the retail package. This is a major oversight with serious consequences.

Unless you plan to only sell your product online, or to industrial customers, the retail package is just as important as the product itself. Sometimes it is even more important.

You can have the greatest product in the world but if your retail package doesn’t quickly convey this to the customer it won’t sell. Always remember, nothing matters without sales!

There are generally two types of retail packages used for electronic products: clamshells or boxes. Smaller products tend to commonly be packaged in clamshells, whereas larger products favor retail boxes.

Retail packaging can be as important as the product itself.

Both clamshells and retail boxes usually consist of two pieces: a custom shaped plastic piece to hold and protect the product, and a cardboard artwork piece to convey your sales message.

Just as with your product’s enclosure, the custom shaped plastic part of the package will require the development of a 3D model. Then an injection molds will need to be purchased.

For clamshells, one cost-saving trick is to use a stock clamshell with a custom molded blister (the part of the clamshell that custom fits over your product). The molds for a custom blister will be much cheaper than molds for a fully custom clamshell.

The clamshell insert card can also initially simply be printed on regular paper prototypes, but eventually you’ll want to upgrade to a thicker card stock which requires stamp printing.

What is the Cost to Scale from Prototype to Production?

Finishing the prototypes of your product is a major accomplishment so congratulations! But don’t get too excited.

It’s a huge step to go from prototypes to large volume production. It’s probably one of the most underestimated steps in launching a new hardware product.

Electrical certifications

Most entrepreneurs forget to factor in the cost to get their product certified. This is primarily true if the product is electrical in nature.

Certification costs may range from only a few thousand dollars up to as high as fifty thousand dollars. It really depends on the product and to a large extent how any wireless features are implemented.

Just keep in mind certification isn’t required until you are ready to begin selling the product. In many cases you can also perform small sales tests without the need for certifications.

The main certifications required for electronic hardware products include:

FCC certification is required for all electrical products that will be sold in the United States.

Other countries will require their own similar certification. So if you plan to sell your product in multiple countries be prepared for the costs to certify your product in each country.

All electrical products radiate at least some electromagnetic energy so governments want to ensure they don’t interfere with RF communication.

The FCC (Federal Communications Commission) classifies two types of certification. Wireless products are classified as intentional radiators because they intentionally radiate radio waves.

Electronic products that don’t purposefully radiate electromagnetic energy, or that use pre-certified modules for wireless functionality, are considered non-intentional radiators.

Modules are pre-certified electronic circuits developed to perform a single function and to be incorporated into other designs.

Products classified as intentional radiators will cost about 10 times more to certify than non-intentional radiator products. This is the reason most companies developing products with wireless functions begin by using pre-certified modules.

Later, once the product is a proven success and higher volumes are being manufactured then the design is transitioned from a wireless module to a custom wireless design so as to increase the profit margins.

Underwriters Laboratories (UL) or Canadian Standards Association (CSA) certification is required for any product that will be sold in the USA or Canada that plugs directly into an AC electrical outlet.

Products running only on batteries with no recharging capabilities do not absolutely require UL/CSA certification.

Also if your product is only charged using a USB charger then UL/CSA certification is not required. If you plan to include a custom USB charger with your product then that component will need to be certified.

However, most large retailers and insurance companies do require UL/CSA certification for any electronic product regardless of whether it plugs into an AC outlet. So unless you plan to only sell your product online you will need this certification.

Many electronic hardware startups choose to start with only online sales, then later obtain UL/CSA certification so as to sell to larger retail chains.

This is a smart strategy since there is no point in spending tens of thousands of dollars on certification until you know the product actually sales.

CE certification is necessary for electrical products that will be sold in the EU (European Union). It is similar to a combination of FCC and UL certifications.

RoHS certification guarantees that the product is free of lead and is necessary for any electrical product that will be sold in the European Union (EU) and California.

However, because California is such a huge market, most companies have their product RoHS certified if it will be sold in the USA.

In most cases it doesn’t make sense to stock both a RoHS certified model and a non-certified model. This certification tends to be significantly more affordable than the other certifications.

We’ve covered the certifications required in the USA, Canada, and the European Union. There are numerous other certifications required for all the various other countries and regions.

If you plan to sell your product in a country we’ve not discussed then you should plan on spending some time researching the certification requirements for that country.

For more details about certifications be sure to read this article.

Setting up manufacturing for mass production

The transition from prototype to mass manufacturing is a complex process that most people severely underestimate. Realistically, you can expect it to take about a year to make this transition.

Having a finished prototype is a long way from having a mass manufactured product.

I recommend starting with a local manufacturer in your own country (if possible). Later, once your manufacturing volume approaches 10k pieces, then you can migrate to an Asian manufacturer.

This strategy allows you to work out all of the manufacturing bugs before going offshore. Debugging problems with an offshore manufacturer is much more complicated.

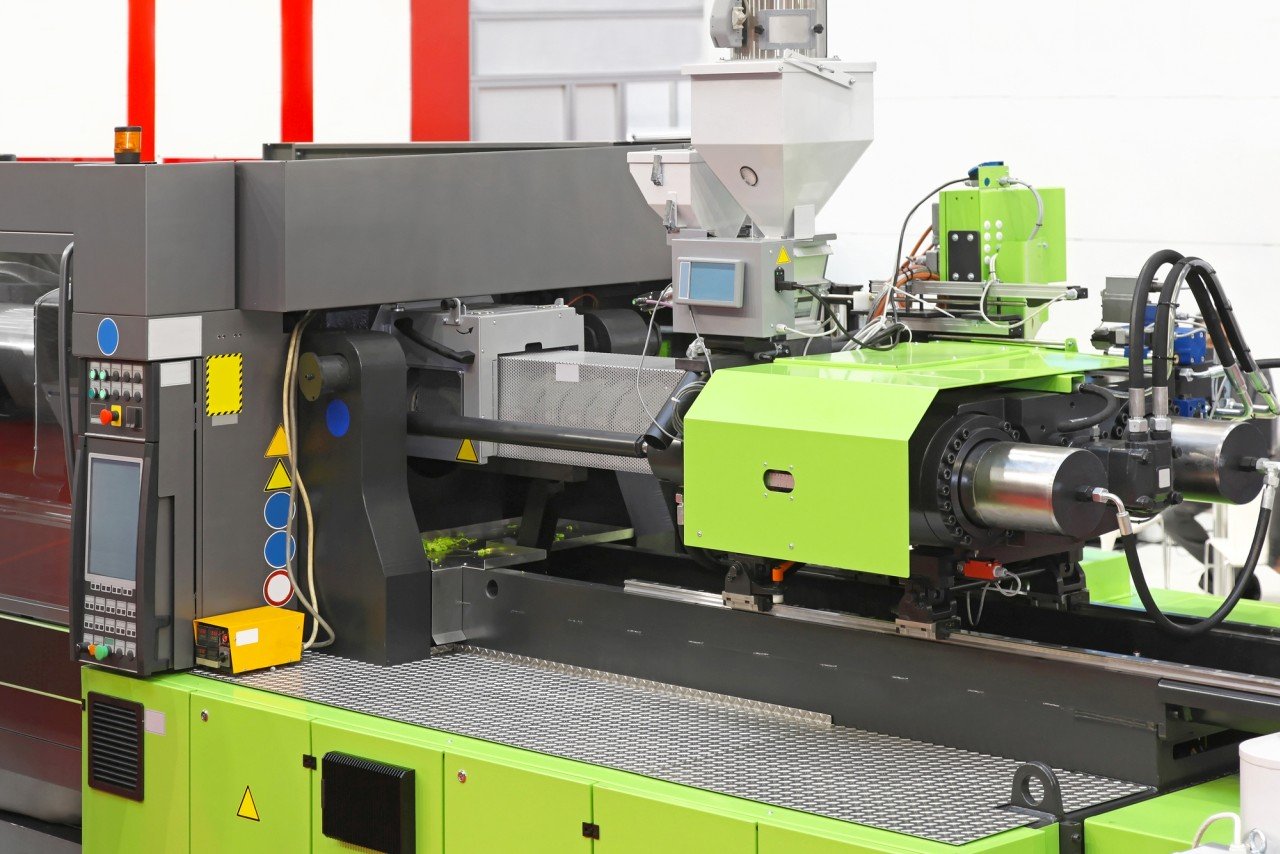

Injection molding machines are used to produce plastic parts in high volume.

Although the electronics will likely be the most complex part of your product to develop, the plastic will usually be the most complex part to get setup for mass manufacturing. This is primary due to the need for high-pressure injection molds.

The injection molded parts needed for your product (enclosure, retail package, etc.) will likely be one of your biggest costs. Injection molds, especially those used for high volume manufacturing, are very expensive.

Just about any product will require at least three molds (front and back side of enclosure plus one for the retail package); however, most products require 4-6 molds.

Mold cost is mostly determined by the hardness of the metal used (higher volume molds use harder steel), the number of cavities, and the use of any side actions.

In most cases it’s best to start with a single cavity mold that uses a softer steel, and that is considered a simple pull mold (meaning no side actions are required).

An injection mold consists of two pieces of metal that are pushed together using high pressure to create a cavity in the shape of the desired part. Then, molten plastic is forced into the mold.

The main advantage of injection molding technology is that it’s a fantastically cheap method of producing millions of copies of a plastic part.

There are two big downsides to using injection molding: the high cost of the molds that I’ve already mentioned, and the limitations on the shapes that can be produced.

The high mold cost is mostly due to the fact that the molten plastic is injected over and over at extremely high temperature and pressure. This means the mold must be incredibly durable.

To tolerate these extreme conditions injection molds are created using a hard metal such as steel. The more injections the mold must tolerate, the harder it must be and the higher it’s cost.

For example, you can use aluminum molds to make a few thousand units. Aluminum is soft so it degrades very quickly.

However, it’s also much easier to machine (i.e. carve) into the desired shape, so it’s cost is significantly lower. As the required volume for the mold increases so does the necessary metal hardness and therefore it’s cost increases.

A single-cavity mold made from a softer metal may cost a couple thousand dollars and be good for a few thousand units.

Whereas, a multi-cavity mold made from a really hard metal can potentially pump out millions of units, but it will cost you tens of thousands of dollars, perhaps as much as $50k.

For more details on injection molding see this blog article.

What is the Cost to Manufacture a New Product?

The landed production cost is the final cost for your product landed in your warehouse.

No doubt about it, the landed production cost is your most important cost. It tells you how much inventory will cost, how much you can sell your product for and how much profit your startup can make!

Also, unlike the development and scaling costs, it’s a cost you’ll continually face for as long as your company exists.

In the video above I show you how to estimate the production cost for your PCB. This video is just a short clip from my full course where I teach you how to estimate the manufacturing cost for your ENTIRE product.

The landed production cost is the total cost to produce and transport a single unit to your warehouse. If you are successful you will have a very long, intimate relationship with this number. You will always be striving to reduce this cost so you can ultimately make more money.

For most products you can estimate that your suggested sales price will be 3-5 times your landed production cost.

Inventory is always one of the biggest costs for hardware companies. Your inventory cost is just your product cost times the quantity. So in order to estimate your inventory costs you need to first know your production unit cost.

Needless to say, you need to know your landed production cost as soon as possible. There’s no point in spending years developing and scaling a product that can’t ever be manufactured and sold at a profit.

Some of the many costs that make up the landed production cost include:

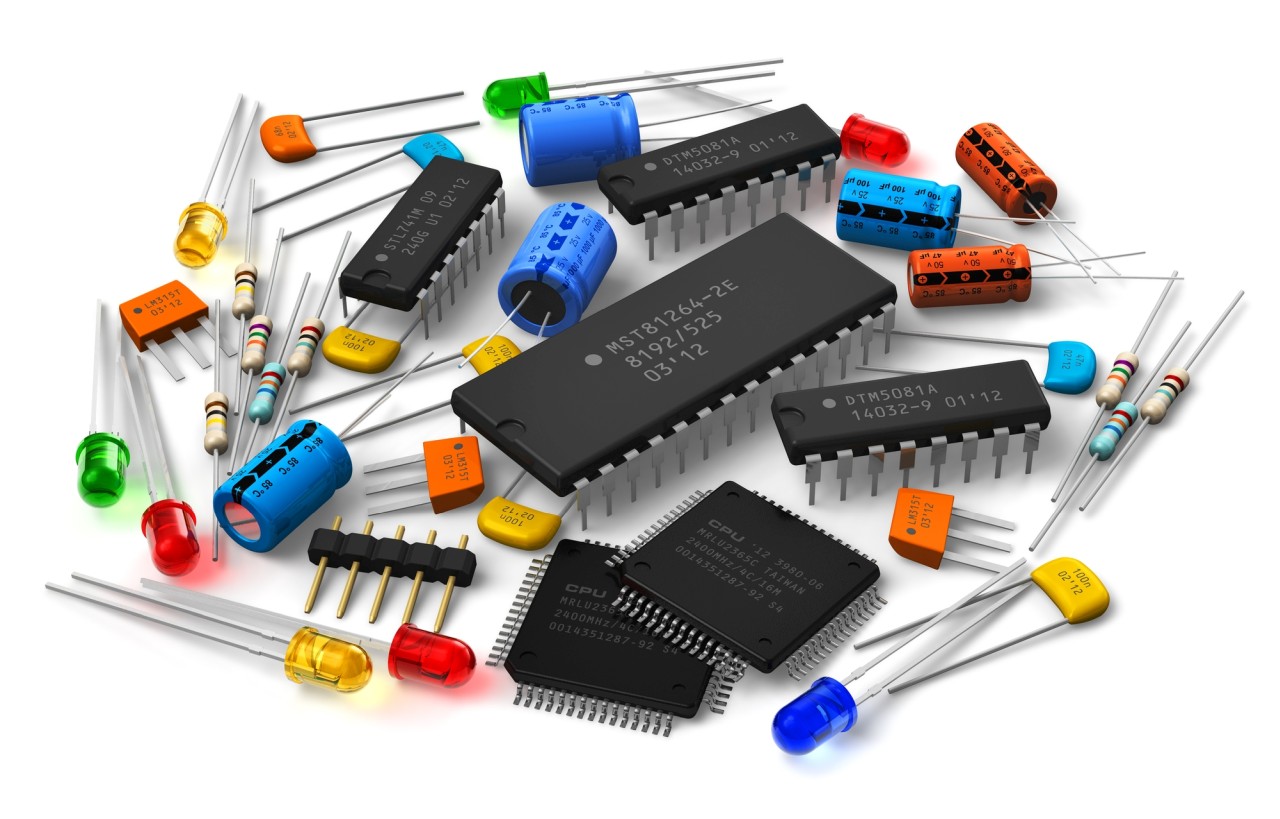

Electronic components

For electronic hardware products the cost of the electronic components will likely be the most difficult to accurately determine.

This is because considerable engineering design work is necessary in order to know which components are required for your product.

Determining the electronic components needed for a new product requires considerable engineering effort.

A lot of startups wait until their product is completely designed and prototyped before they try to determine their components cost and ultimately the production cost.

This is a mistake because you really need to have an estimate of this cost BEFORE you spend tens of thousands of dollars developing the product.

There may be some desired features for your product that you determine are too expensive to include in your first version. By estimating your components cost upfront you can avoid developing a feature that isn’t profitable or necessary initially.

Circuit board (PCB)

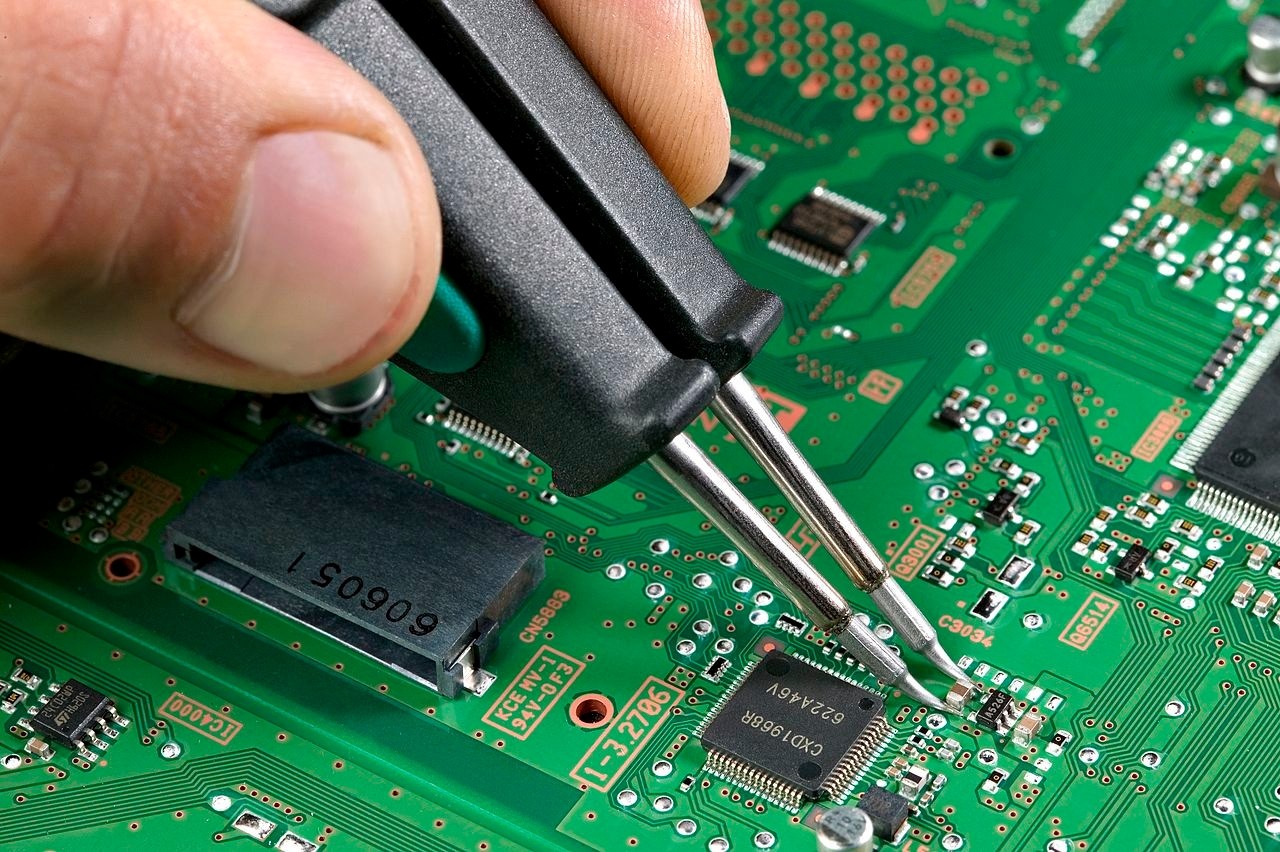

Just as with your prototypes, producing the electronics is a two step procedure. First the blank PCB is produced, and then all of the electronic components are soldered on to the board.

The cost of the blank PCB is mostly determined by its size and the number of routing layers. At a bare minimum two routing layers (top and bottom) are required; however, most designs will require from 4 to 6 layers.

More complex designs may require 8 layers or more. Increasing the number of layers generally allows you to reduce the overall size of the PCB.

The cost to assemble the PCB (i.e. solder down all the electronic components) is primarily determined by the total number of components, the minimum pin pitch, the use of leadless packages such as QFN or BGA, and whether components are soldered on both sides of the PCB.

Assembly of the PCB is performed by automated placement machines.

Keep in mind that the cost to produce your assembled PCB in volume will be many times cheaper than the per unit cost of the prototypes. Much of the cost is the initial setup so as the volume increases the setup cost becomes minimal.

That being said the setup costs for the electronics pale in comparison to the setup costs for the plastic (i.e. the injection molds).

Custom plastic parts

The cost you’ll pay per unit for any production plastic pieces is primarily determined by the weight, size, mold time, and type of plastic used.

The size and weight for each piece is dependent upon your design so there isn’t much you can do to control those variables short of making your product smaller or less durable (thinner plastic).

You can eventually increase your production speed, and reduce the part cost, by using multiple cavity molds. A multi-cavity injection mold allows you to produce multiple copies of your part with a single injection of plastic. But having multiple cavities also significantly increases the mold cost.

Don’t jump into buying multiple cavity molds until you have worked through any tweaks or changes to your initial molds. It is wise to run at least several thousand units before upgrading to multiple cavity molds.

Increasing the number of mold cavities is usually the best method for reducing the plastic part cost since size, weight, and the type of plastic directly impact the end product.

Other mechanical parts

Some products will require various other parts such as stamped metal pieces (for internal shields, etc.), springs, gears, screws, motors, and etc. In many cases, stock components can be used which will eliminate any scaling costs.

Final product assembly

Once the various individual components are ready the next step is to assemble them to form your final product. The cost of this step is almost entirely labor costs.

This means eventually you’re likely to need to have final assembly completed at a location with low wages such as Asia.

The cost for final product assembly is mostly labor costs.

Product quality testing

Once the final product has been assembled it needs to be tested to confirm it is fully functional and meets all of the quality specifications.

Some testing of the electronics may also be done before final assembly so as to prevent wasting the cost of final assembly for a unit that has problems with the electronics. As your scrap rate decreases you’ll likely perform all testing after the final assembly is completed.

Improper testing, and ultimately shipping bad units to customers is a common mistake and one that can spell death for your startup.

Many entrepreneurs tend to rush their new product to customers but shipping bad units will start your company off with a bad reputation which can spread quickly online.

Manufacturing scrap

No manufacturing process is ever perfect and you are guaranteed to have some faulty units. Initially this may be 10% or more, but as time goes on and you optimize your manufacturing process you should be able to reduce this number to only 1-3%.

Retail and shipping packaging

Packaging costs depends on whether your product will be selling in retail stores, or primarily online. For products sold in retail outlets having optimal retail packaging is a critical priority so packaging costs will be significantly higher.

The packaging cost can be greatly reduced if you plan to only sell your product online, via TV, or to industrial customers.

High-end retail packaging (i.e. full color boxes with custom plastic inserts) can be really expensive (costing as much as $5 to $10 each) so in most cases it’s best to start off with more simple packaging to minimize your costs. This is one reason it may be best to focus initially on online sales.

Don’t forget to include the cost of the master carton that will be used to ship your packaged product. The master carton cost is typically quite low since it usually just a cardboard box and the cost gets split between multiple units. Nonetheless, it’s important to include it in your cost calculations.

If your product requires a retail display stand then that can add another cost to your package cost calculations.

Product returns

Just like you are guaranteed to have some faulty units that must be scraped you’re also guaranteed to have at least a small percentage of unhappy customers that wish to return their purchase. So be sure to include this in your final production cost.

Just as with the scrap rate your return rate should decrease as you optimize your product, packaging, and customer service.

Shipping and logistics

Most products will ultimately be manufactured in Asia. This means your finished product will first need to be trucked from the factory to the local sea port. Then it will be loaded on a cargo boat for shipment to your target country.

Then, once the boat arrives in your country you’ll need to truck it from the port to your warehouse or directly to your customer.

Most products coming from Asia are shipped by sea on huge container boats.

In rare cases you may wish to ship via air cargo, but the cost will be significantly higher than shipping via sea.

For shipping via truck it’s the weight that primarily determines the shipping cost, and for shipping via boat it’s the volume that determines the cost.

Taxes, Duties, and Tariffs

Don’t forget the taxes. Both the country of manufacture and the country of import will charge duties which need to be included in the final landed cost. Although, some product categories may be exempt from export and/or import taxes.

Each product classification has a number known as a Harmonized Tariff Schedule (or HS code). Once you’ve determined the HS code for your product then you can look up the export and import duty rates.

Conclusion

The cost to launch a new electronic product can be overwhelming, especially for entrepreneurs and startups. Development costs will be your first financial obstacle to surpass, and scaling costs will be your largest cost.

However, the landed production cost will definitely be your most important cost since it determines your profit, sales price and inventory cost.

You’ll eventually move beyond the development and scaling costs, but you’ll have to live with the production cost indefinitely.

Other content you may like:

- Lesson 4: The Strategic Way to Develop and Sell Your New Electronic Hardware Product

- Game-Changing New Technology for Product Prototyping [YouTube]

- How Much Does a Prototype Cost?

- From Prototype to Mass Manufacturing: Understanding Scaling Costs for Physical Products

- Why Hardware is Hard, But Easier Than Ever

Great article, I would recommend all my fellows to read this article. nicely structured. Thanks for this information. I have subscribed to for your newsletters

A great piece of information. I think this is what I was exactly looking for. All tips in a single click. I would definitely try to follow these suggestions

Thank you!

Great Article, thanks!

Would be great if there was a table with example ratio’s of the various costs.

Can help a lot in the initial financial planning when still prototyping and the final BOM isn’t set yet. Specifically – the ratio between BOM and COGS.

Thanks again!

Hi John,

Many thanks for a very informative and well thought out set of blogs (tutorials) on getting a prototype idea through to mass production.

A couple of questions:

i) How would you flash a large number of MCUs (say 30K+) with the required firmware? Is this a service that a PCB manufacturer can provide, or would you need to go to some other dedicated service provider that would have the automation

tools to flash your software into such a large number of units?

ii) Are pre-certified modules, say for WiFi or Bluetooth (housed on their own ‘mini’ circuit boards) generally OK to be incorporated in a custom PCB with SMT processing? I am thinking particularly in terms of the HC-05 Bluetooth

transceiver module (which is mounted on its own mini circuit board). Some of these units even have a transparent plastic covering around the entire unit. Would you see any problems in using such self-contained units into your customised PCB?

Once again, many thanks.

Michael

Hi Michael,

Thanks for the positive comment, and I’m glad you are finding my blog to be helpful.

To answer your questions:

1) Typically the best option is to have the MCU manufacturer do the programming before you even receive the chips and mount them on your PCB. Most MCU chip makers (and modules) offer this service.

2) Yes. Wireless modules are very commonly mounted on SMT boards. They are always on their own PCB, and most are designed to be SMT mounted on another PCB.

Okay, hope this is helpful. Don’t hesitate to ask if you have other questions.

Thank you John . Quick question , If i use Particle electron (3G cellular ) in my custom PCB and remove some components i dont need like led’s etc .Will it be still considered pre-certified module?

https://www.particle.io/products/hardware/electron-cellular-2g-3g-lte

Hi David,

Are you referring to removing components from the Electron itself, or do you mean from your custom PCB? That’s not a situation I’ve ever come across but I’m pretty confident it that modifying a pre-certified board at all would lose the certification. Is there really any benefit from removing these components? Would you do this for all of your production units?

Thanks for the comment and question.

A great piece of information. I think this is what I was exactly looking for. All tips in a single click. I would definitely try to follow these suggestions. I really enjoyed this post and I hope you will keep posting this kind of post in future.

Thank you Rick! I’m glad it was helpful.

John

Hi John,

Regarding the certifications required, if you use a standard power adaptor (like those used by computers, other devices) and power your unit via the barrel connector; do you necessarily need to get certification for a non-radiating device (mainly small electric motor and heater)?

Great website, and thanks for the recent Arduino guide book.

Cheers,

Hi Anil,

Thanks for your question. If you use a standard UL-certified power adapter then there is no need for you to obtain UL certification.

The other type of certification is EMI (ElectroMagnetic Interference) which in the U.S. is FCC certification. This certification doesn’t depend on the power source. Instead it depends on whether the product “intentionally” radiates electromagnetic energy (radio waves). If anything in your circuit operates at 9kHz or higher then you need at least non-intentional radiator EMI (FCC) certification. If your circuit intentionally radiates EMI then you will need intentional-radiator EMI certification, unless you use pre-certified modules for any wireless radio functionality.

Okay, I hope this answered your question. Let me know if you have further questions, and I’m always happy to help!

Best wishes,

John

Part 3 was quite a revelation to me as I haven’t reached that far the times I’ve developed a product. Definitely will have these costs in mind next time!

Hi Roberto,

Yeah there are so many little costs that go into the final manufacturing cost for a product. I find, like you said, that these are some of the least understood costs. Most entrepreneurs focus all of their effort on development costs, but I argue that the actual manufacturing cost is the most critical cost to know asap.

Thanks for the comment!

Thank you for your download. I want to know where the Dimitri makes and soldering their PCB boards. Where I go only Make the PCB but not solder. If you can help me I’m happy.

José da Conceição

Check out Seeed Studio (China) or Screaming Circuits (USA).

Best wishes,

John

John…would it be possible to speak personally with you regarding my project?

Yes, please just email me directly at info@nullpredictabledesigns.com and I’ll be happy to help.

i’m very happy for your reply. it helps a lot and i’m learning a lot. thanks a lot.

i have another question, are their available custom made Molds? if yes, then what if i want a unique product shape that’s isn’t available? does that means i have to get one manufactured for me? if yes then who are the mold manufacturers and where do i find them, as well as the CAD designers of the chosen mold.

and what cost saving strategy will you recommend to a fresh startup with regards to enclosure cos i learned injection mold cost a lot?

best regards

Hi John

i have a little question to ask, i’m just an electronics graduate and i love making things, and entrepreneurship talks.

my question is do you recommend cnc machining for a low volume manufacturing after one is done with prototyping ?

second, i’m learning about injection molding but i’m confused, already you mentioned the limitations of the injection mold. i also want to know if say i want to make varieties of products each with a unique style and shape does that mean i have to get cavity/mold for each of the product ?

thanks in advance.

Hi Abba,

Thanks for the comment. CNC machining is usually only a viable option for producing a small number of prototypes. It’s not normally used for production. CNC machining is used to produce the injection molds used for production, but direct CNC machining of your product is only used for prototyping.

Yes, if each product has a unique shape it will require custom injection molds. Also keep in mind that a unique mold is required for each piece of the enclosure, and for most products that means at least two (front side and back side). So if you have two shape versions of your product you’ll likely need at least 4 molds unless you limit the shape differences to one side.

Hope this helps, best of luck.

I find it so interesting that prototype stamping has been made available with the advent of 3D printing. I can see this having huge applications for the metal industry with new sheeting techniques. Thank you so much for the helpful stamping information.

Thanks for the vital informations provided. Can I make use of your company for my mass production?

Hi John, Good article. Do you have a relative share of all the costs? For example, what % of total are the landed manufacturing costs? etc. And what about costs (and relative %) for data and connectivity for newer IoT products?

Hi John,

Thanks for the perfect article and your support for electronics engineers, we offer similar services in our country .Our mission is supporting Electronics start up companies in production and marketing. here is our website_electronicassembly.ir

it is in Farsi language but your visit make us happy 🙂

Very educational article to start up like me.

Thanks Amir, I appreciate the feedback!

John

Hi John,

Good article that I would like to complete with a couple of comments.

Although in theory it may seem to have impact on the cost of the process, my experience is that the technology of common use components (QFN, BGA or SO) hardly affects the cost of their assembly.

Nowadays, automatic SMT machines (SPI, P&P, Reflow) manage with the same efficiency and reliability classic SO packages (50 mils pitch) and high density QFN o BGA (20 mils pitch). Neither scrap nor test cost are substancially higher using such different technologies.

However, a relevant aspect that has not been considered is the manufactured batch size, since the costs of preparation of the assembly line must be supported by each of the units manufactured.

Kind regards.

Thanks for the helpful comment Inigo!

Best wishes,

John

John, you did not mention California Energy Commission (CEC) certification required for products with rechargeable batteries. I was unaware of it until recently and I can find very little practical information about the testing requirements and cost of testing. And is it really a requirement to sell in California (and some other states)? What can you tell me about this?

Hi Paul,

Thanks for your question. I’ve not heard of or dealt with this certification before. I’ve been in contact with the CEC to get some clarification. So far it appears as if their only required CEC certification is related to appliances and not lower power electronic devices. However, I’m still waiting on them for further clarification. I’ll update this comment with their final answer.

Best wishes,

John

John, I hope your assumptions are correct, but I have found no exceptions for “small devices”,

summary from the regulations:

http://www.energy.ca.gov/2014publications/CEC-400-2014-009/CEC-400-2014-009-CMF.pdf

Section 1601. Scope.

This Article applies to the following types of new appliances …

(w) Battery charger systems, except those:

(1) used to charge a motor vehicle;

(2) for FDA approved medical device;

(3) for an illuminated exit sign

(4) with input that is three phase

(5) that are battery analyzers; or

(6) some uninterruptible power supplies

…..

Section 1602:

“Battery charger system (BCS)” means a battery charger coupled with its batteries or battery chargers coupled with their batteries, which together are referred to as battery charger systems. This term covers all rechargeable batteries or devices incorporating a rechargeable battery and the chargers used with them.

Thanks Paul, CEC never got back with me. I’ll continue to look into this and update this article appropriately. I guess the term “appliance” is a bit confusing since most don’t think of a small electronic gadget as an appliance.

Best regards,

John

Really awesome article.Got lot of info

Thanks Sampat! I really appreciate the positive comment.

Best wishes,

John Teel

Hi John,

Thanks for the article, it’s very informative as well as all your letters within email subscription. You didn’t mention laser cutting which also might be used for prototyping and small scale production, we as a r&d team use it along with 3d printing and CNC machining. I think PCB production cost depends on region/country and could be much cheaper than $1-2k per iteration. For instance, in my town it will cost no more than $150 to produce ten 2 layer PCBs with solder mask and annotation on both layer within 1 week period. This is true for the first batch. If you repeat with the same pattern the cost dramatically decreases.

Thanks for the helpful comment Dmitry!

Best wishes,

John

Dimitry, where are you from? Which country are you from? Can you share which company can develop PCB at $150? Contact information? Any US based companies that are reference by chance? THanks! Jason

Awesome info, this really helps, thanks John

Thanks Milton, glad you found it helpful!

Best wishes,

John

John,

Nice article but not sure whether I can ask the question here or not. My question is if I have an idea, can you guys help me from scratch like designing pcb and components basing on my requirement? Thanks in advance.

Thanks for the comment. Yes we can help you design the PCB, and I’ve replied to your email as well. Best wishes.

Hi John,

In continuation from where I stopped yesterday (speaking of my remaining 25% inquiry), here are some other things I will like to know:

1. Who creates/provides the CAD rendering of the product… you or me? There is no mention of that in your article.

2. How many working prototypes (in various colors) do I get at the end of the design/development process?

3. What is the average completion time frame (in this case speaking of a less complex consumer electronic product)?

These are the questions I have for you for now. Looking forwarding to hearing back from you soon again.

Thank you!

Michael

Seattle, WA

Hi Michael,

Thanks for the questions!

1) You’ll need an industrial designer to create the 3D CAD model for your product’s enclosure. I do provide a 3D model of the assembled Printd Circuit Board (PCB) but not the full product. I focus on electronics design only. I can definitely recommend an industrial designer though.

2) As many as you want, up to a few hundred. Keep in mind though that any prototypes of the plastic (i.e enclosure, etc) will be made by a different process (3D printing) and a different type of plastic than will be used for production (injection molding). So normally you only want to order 5-10 prototypes. If you need more than that then I recommend moving up to low-volume injection molding.

3) Most products take about 9-12 months to totally complete (electronics design, 3D model design, programming, mobile apps, retail package design). You’ll likely get a prototype much sooner, but to work out all of the little bugs takes longer.

Okay, I hope that helps. Email me any time if you think of more questions. Regardless if you use my company or not I’m happy to help answer questions.

Best wishes,

John Teel

Predictable Designs

Hi John,

As always, thank you so very much for taking time out of your busy schedule to respond to my inquiries, and in the process providing me invaluable insights.

My small team of Startup Entrepreneurs and myself have already decided on hiring you and/or your company to meet our Electrical Engineering needs. Our decision took into consideration your professional qualifications, and the numerous very respectable recommendations of your company’s website.

We are highly impressed… and that is to say the least!

That said, because we are based out Arizona, we would like to see the following legal instruments put in place at the minimum:

1. Non-disclosure Agreement

2a. Contract

2b. Contractual Timeline

Please let me know your thoughts on this, and perhaps more.

Regards,

– Michael

Seattle, WA

Thank you Michael for the very positive comments! Can you please email me directly at info@nullpredictabledesigns.com to continue this conversation privately.

Best wishes,

John

Hi John,

Fully agreed! I will be contacting you shortly via email at info@nullpredictabledesigns.com.

Looking forward to working with you!

– Michael

John,

Thanks for taking the time to share some very important insights about product development… very helpful for a Startup Entrepreneur like myself. Roughly 75% of my questions were answered… so that means there is roughly 25% more questions that remains unanswered. Still though, I am eagerly anticipating working with you in the not-too-distant-future.

Michael,

Seattle, WA

Hi Michael,

Thank you! Feel free to post your remaining 25% more questions and I’ll try to answer them, or just email me at info@nullpredictabledesigns.com with your remaining questions.

Best wishes,

John

Nice article. Thanks for the info.

Thanks Jeremy! I hope it helped you.