How Much Does a Prototype Cost?

One of the first major steps on the road to bringing a new product to market is the creation of a prototype. Learn just how much the prototyping process is going to cost you.

The cost of a prototype can be broken into two major parts: the engineering cost to design it, and the actual cost to produce it.

The total cost of the prototype (assuming an electronic product) usually includes the cost to manufacture the custom Printed Circuit Board (PCB), plus the cost of components, assembly, and the enclosure.

For most products the engineering costs will dominate. They also can vary greatly depending on several variables but especially on the product complexity.

Engineering fees may be only a few thousand dollars for a simple product up to hundreds of thousands of dollars for a really complex product.

Ultimately, the best way to reduce your prototyping cost (in fact, all of your costs) is to simplify your product as much as possible as early as possible.

Many times a seemingly “simple” feature can dramatically increase the development complexity and cost.

Even something as simple as the location of a button can cost you thousands of dollars extra down the road when it is time to purchase injection molds to mass manufacture the enclosure.

Don’t forget all of the steps that lie beyond the initial prototype on the path to market. This includes costs like electrical certifications and injection molds.

Reducing product complexity drastically reduces all of these costs making it more feasible to bring the product to market on a restricted budget.

As another example a member in my Hardware Academy recently shared his product details to get feedback from myself and the other experts. This entrepreneur was quite technical and had thought a lot about the product details.

But, he didn’t understand all the future consequences of the features he had specified.

Immediately we explained to him there was one product feature that was driving up all of his costs including his development, prototyping, electrical certifications, and injection mold costs.

You know what? This feature wasn’t even essential and we were able to suggest a much more feasible solution. This small change likely lowered his prototype cost by about 3 times!

Keep in mind that asking your primary developer to help simplify your product creates a conflict of interest. The more complex the product the more money they get paid.

This is why I recommend working with experts independent of your primary developers to help simplify your product before you begin full development.

Engineering Costs

Most engineers work on an hourly basis especially on larger projects.

Be warned though that it’s impossible to quote the development time for a complex product exactly down to the hour. So you should expect your costs to exceed what is initially estimated.

The hourly rate charged by design engineers varies depending on location, years of experience, education level, area of specialty, success with previous projects, etc.

According to the Institute of Electrical and Electronic Engineers (IEEE) the average rate for an independent contract engineer is $125/hr. in the United States.

Roughly, hourly rates for an engineer in the U.S. can vary from $50-$300/hr. This is a big variance but once again it all depends on the experience level of the engineer.

For example, a more expensive engineer may be able to work twice as fast and produce a higher quality of work, both of which will lower your overall cost.

You can hire engineers outside of the U.S. typically much cheaper with hourly rates varying from $25 to $75 per hour.

Regardless of their location or experience level you should always have other independent engineers review their work along the way. This is especially critical if you don’t have the experience to judge their quality of work.

For most products you will need at least an electronics engineer, a programmer, and a mechanical engineer.

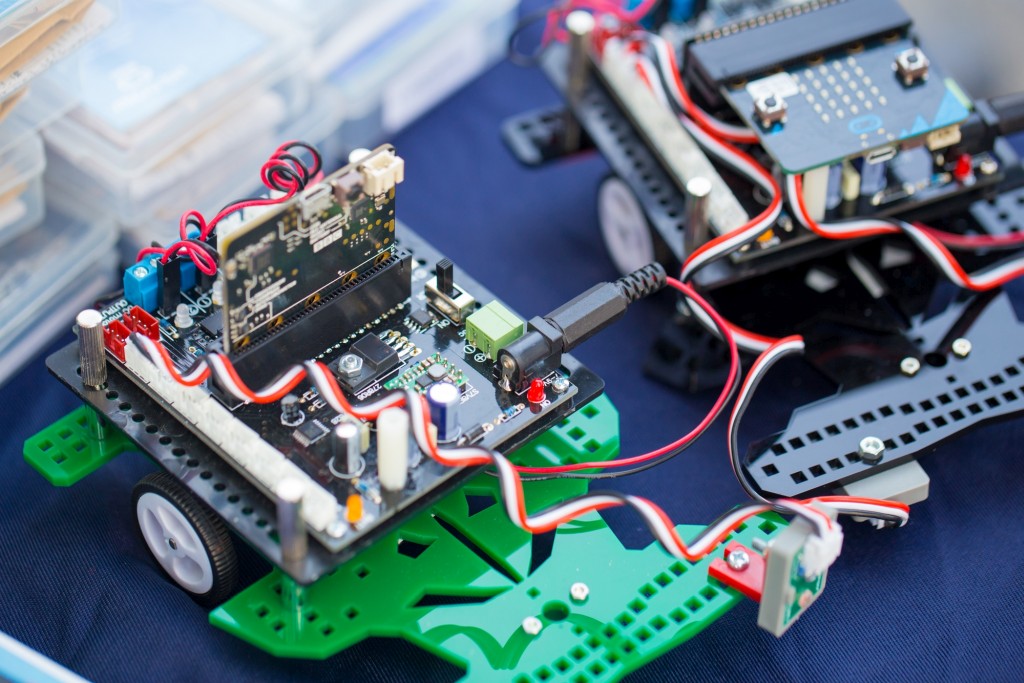

Electronics Prototypes

The cost you will pay for prototypes of your Printed Circuit Board (PCB) will depend on many variables. The most critical one likely being where you have the boards produced.

If you choose to have your boards produced in China then you will pay only a couple hundred dollars for a few boards, but that will increase to likely over $1,000 if the boards are produced in the U.S.

For producing your prototype boards in China I highly recommend PCBWay, Bittele Electronics, or Seeed Studio. For production in the United States I primarily recommend Sunstone Circuits.

Most boards require 4 layers. Adding more layers can help reduce the board size but at a higher board cost.

Although the board cost increases as the board size increases, the number of layers has a much greater impact on cost. So bigger boards with few layers are cheaper than smaller boards with more layers.

Advanced PCB technologies, like blind and buried vias, can also be used to decrease board size even further. But these technologies will add thousands to your prototyping costs so only use them if absolutely necessary.

In most cases, only wearable devices can justify the added cost of blind and buried vias to reduce your board size.

In addition to the board production and assembly costs, there is the cost for the electronic components.

But for most products the cost of the components is minimal and usually totals less than about hundred dollars for a few boards.

Enclosure Prototypes

As for the enclosure (i.e. the case) the cost depends if you want a custom design or if you can get by with a stock enclosure.

A stock enclosure will usually only cost a few dollars. A custom enclosure prototype will cost several hundred dollars depending on the size, complexity and number of pieces needed.

For prototyping any custom plastic or metal parts I highly recommend Proto Labs based in the U.S. They offer various prototyping services as well as creating low volume injection molds that allow you to produce a few thousand parts.

A lower cost option in China is again Seeed Studio which offers both 3D printed and CNC machined prototypes.

Try to get by with a stock enclosure as long as possible to save money and complication. However, most products eventually require a custom designed case so you can’t delay that complication indefinitely.

Conclusion

Keep in mind that all of these costs will reduce significantly as your production volume increases. The cost of a prototype is not to be confused with the manufacturing cost for the product.

Even going from 2 units to 20 units will have a huge impact on the unit price.

What costs you a thousand dollars for a single prototype may only cost a couple of dollars once you purchase much higher volumes.

The most important thing to remember is you need to spend significant effort simplifying your product to make it more feasible to prototype and ultimately bring to market.

Here’s an article that you may find helpful where I break down in more detail every development cost to go from idea to prototype.

Hello john i want to know how much for a prototype of un new electrical motor

Hi John, is there a way I can contact you? I want to get your input on my product.

Sure, you can reach me here: https://predictabledesigns.com/contact/

However, I don’t really have the bandwidth available to provide you much input unless you join my Hardware Academy platform. Academy members always get my high priority. In the Academy you can get all of the help and input from me as you need plus you get help and advice for numerous other experts too.

Cheers,

John

Hi John..

I’m a mechanical engineer from India. And I wanted to design a pcb for a smartphone. Could I know how much will it cost approximately?

There is no general number and it really depends on the product complexity and location of developers. Designing the PCB for a smart phone is extremely complex and I would never recommend an entrepreneur design something so complex. Better to find existing designs and work with manufacturer to customize it.

Thanks John

Hi John

Thanks for the information. I’m wanting to prototype a nightlight, I’m assuming since they are small the circuit board would cost more? I thought it probably wouldn’t be too complex so hoping that will assist with the cost.

A smaller board is actually cheaper to manufacture. They can be more expensive to develop if there is a lot squeezed on the board, but that’s not likely the case for a nightlight.

Hi John, thanks for the article! Are the estimates still relevant in 2019 or you would adjust them?

Thanks Dmitry! Yes, these estimates still apply in 2019, and they haven’t changed much.

Thanks!

Is it normal to be charged for brainstorming, meetings with client to provide updates, initial kickoff meeting?

After the first introduction, where you have established a desire to work together, absolutely. A few hours to survey compatibility should be enough. Then you make a business agreement and move on.

Keep in mind, that the effort expended in the beginning to clarify needs and find innovative solutions are often the most productive dollars spent on a project. Those are the times where you want the best engineers in the room to find what they can contribute. As your project progresses, it becomes less engineering, and more implementation. But if you try to avoid paying for the engineering phase, you are actually short changing yourself.

At work, we have a project that requires making circuit board prototypes in production. I have been wanting to do a cost analysis for the production, therefore, all your figures were very helpful to me. It is interesting to me how the most expensive engineer per hour can save money for the project.

Hello,

I need some advice on how much will it cost me to have my invention built into a prototype. I need a software developer to make my video game prototype and will like to know the cost of the person who is going to develop my video game project as well the cost of the hardware operating system. What help can you give me.

If your board is small and you want few boards, take a look at OSH Park (https://oshpark.com/). They charge $5 per square inch, provide 3 boards, have ENIG (gold) plating, and ship free anywhere in the world. If you want large boards and low cost or more than just a few boards, Seeedstudio Fusion PCB https://www.seeedstudio.com/fusion_pcb.html will be your best alternative, US$4.90 for 10 boards up to 10*10cm, they are the cheapest

I’ve used http://www.pcbnpi.com Service a few times and was quite pleased with the turnaround time and overall quality. They offer several different packages including full assembly service. That’s really save my time and money.

Creating a prototype is the best part of all “creating”! In mu opinion good solution will be using an advanced technology, like 3D printer (someone said that before). Then you can see how it’s gonna look, also you can do some test on it. In my company ( http://www.vocean.co.uk/ ) we always works on prototypes made by 3D printers 🙂

Hi John, I am an industrial engineer from Turkey and have a question. Do you send the prototype which I want to Turkey? I want to tell about prototype according to your answer. Also thnx for free e-book.

Yes, I can send a prototype anywhere you wish. I have clients in India, Turkey and the UK in addition to my US clients. So no problem.

Thanks for the free downloads, John. A lot of good information. Any idea what I could expect to pay for an Industrial Designer who does mechanical engineering as well ? Thx.

Thanks Frank. You can expect to pay anywhere between $50/hr to $300/hr. I know that’s a big range but it really can vary that much depending on experience level, and how long the line is for their services.

Do you think it is cheaper to buy your own 3D printer and print out a prototype, or is it cheaper to go with a company that does that amongst other things for prototyping? THanks for any feedback.

Generally I think it is best to use a prototype shop instead of buying your own 3D printer, at least for your first product. Once you have a profitable product, and are developing multiple other products, then owning a 3D printer probably makes sense. Of course, some entrepreneurs may like having their own 3d printer, and owning one does allow you to make fast revisions. As for cheaper, using a prototype shop is initially cheaper, but if you do lots of revisions then buying one will pay for itself quickly. Thanks for the comment!

Your article is really invaluable. Do you also prototype hardware machines & what sources of funding do you suggest for a nigeria-based startup innovator?