The 4 Step Process I Followed to Get My Own Hardware Product to Market

I’m going to share with you the four steps I followed to fund my manufacturing, build a global sales team, and successfully sell my product in hundreds of retail stores.

By following the steps I will outline in this article, you will have a much better chance of getting your product to market without giving up any equity in your company or bankrupting yourself.

Back around 2008, I developed and brought to market my own consumer hardware product. My product was a miniature lighting device that illuminated any surface that it was attached to.

I will be using my story to illustrate my process. I took small steps, and then leveraged each small success into larger and larger successes.

My product was a very low cost product that wasn’t financially feasible to sell online. For higher cost products I typically recommend that you begin by selling through your own website.

All of my focus was on building a network of retail stores that sold my product.

Although this article starts with step #1, there are actually several critical steps that need to be done beforehand. This includes early market research, product validation, speaking with potential customers, and estimating your costs.

These upfront steps should all be done before you spend a significant amount of money on a prototype. Don’t rush past these early steps or you drastically increase your chances of developing a product that either no one wants or no one can afford.

Step #1 – The Prototype

Once you have done the necessary due diligence to warrant spending significant money on your product idea, the first step is to get a prototype that looks and works like the final product. You want to accomplish this as quickly and cheaply as possible.

Although you will likely want to start with a crude, proof-of-concept prototype for early testing, here I’m focusing on a prototype that can be presented to potential customers.

I self-funded my startup until I was able to get to the point of having a quality prototype. It wasn’t perfect but it was good enough to start showing to potential customers.

Don’t ever wait for perfection, because you need to get something out there for feedback as soon as possible.

You almost always have to self-fund this first step. It’s very difficult to convince others to put their time, money and energy into your product, until you have a good prototype. It’s also very, very challenging to get investors, manufacturers or retailers interested in your product without a prototype.

This also applies to running a crowdfunding campaign. Typically, if you’re going to do a crowdfunding campaign, you need to have a final stage prototype, or something very close.

Having a prototype that looks and works similar to the final product shows that you’re serious and you know how to execute.

Most investors want to see, first of all, that you’ve invested some of your own money into the project. That just gives them a higher level of confidence that you’re not going to quit, since you’ve invested your own money (and time) in the project.

Investors are always more interested in the execution than in the idea. Having a prototype proves that you’re a doer and not just a dreamer. Entrepreneurs and inventors often tend to be big dreamers that often ignore the execution part of the process.

In contrast, having a real prototype shows that you’re not just doing this for fun. It demonstrates that you’re serious about getting your product on the market.

Note that in this context, by investors I really mean anyone that is considering investing their time, money or resources into your project. This can be retailers, manufacturers, strategic partners, sales people, and financial investors.

On a more basic level, having a prototype proves that your solution is feasible and actually solves the intended problem. It’s way more effective to pitch your product if someone can hold it in their hand and actually use it. Your chances of success will be much higher than if you only have a description of the product.

Despite all the benefits of having a prototype, it’s going to be really difficult to raise money to fund this early stage. Your options are limited to friends and family, and potentially a very few angel investors. Most entrepreneurs have to fund themselves to the point of at least getting to a prototype.

This is exactly what I did. My prototype was, by no means, perfect or ready to be mass manufactured on an assembly line. It was still a prototype created using prototype technology. The plastic was 3D printed and not injection molded at this point.

I explained to retailers and manufacturers that I had a prototype and not a finished product. They were typically understanding of that.

Money is going to be the most limited during this first step. You’re going to have to work efficiently with small amounts of capital, unless you’re lucky enough to have significant capital of your own to self-invest.

But even then, having too much money can be problematic since it may entice you to take shortcuts before you fully understand their implications.

There are several ways you can reduce the cost of a prototype. The best way, if you have the technical skills or you can learn them, is to do as much as possible of the development work yourself.

Are you capable of doing the electronics design, software programming, or 3D enclosure design yourself? Take on as many aspects as you can, and remind yourself that it doesn’t have to be perfect.

But also be aware of your own limitations and that you need to consult with professionals when necessary.

Once you’re able to use that prototype to get more money, then you can hire a professional design engineer to optimize your design into something that can be reliably manufactured.

In the early stages, just focus on trying to get a prototype that looks and works like the final product. Do this as soon as possible, and as cheaply as possible. Then you are ready to move on to step two.

Step #2 – The Big Customer

After completing step one, I used my prototype to get a well-known retailer to express written interest in my product. Like I mentioned previously, this is difficult without having a prototype.

One of the many applications of my miniature lighting device was putting it on your remote control. When you’re watching TV or movies in the dark, you press the light to illuminate the remote control buttons.

Keep in mind this was back when most remote controls lacked effective illumination and where unreadable in the dark.

One of the retailers I focused on was Blockbuster Video. This was quite a few years ago, back when Blockbuster Video was a huge, internationally known company.

There was one reason I focused on them versus a Walmart, Target, Walgreens or Home Depot. I knew that Blockbuster wasn’t constantly being pitched new products like a more general merchandiser.

I encourage you to do the same and to identify some strategic companies that may not be pitched as many products as a general merchandiser.

My product was also a really nice fit for their business because one of the key uses of the product was to illuminate remote controls in the dark.

So how did I make a connection at Blockbuster Video? First, I found the email addresses for several of their vice presidents. I then decided to reach out to their Vice-President of purchasing since he seemed like the most likely decision maker.

I was able to get his direct email address, which is the only way you should reach out to someone at a large company. You need to do the work to find the direct email addresses of the decision makers you need to reach.

Don’t ever send an email to a generic email address, like suggestions@nullblockbuster.com. That’s never going to work! Instead, focus on finding the email address of the decision maker, which is what I did.

I sent him a really short email. I can’t stress enough how critical it is that you make this email short. Just a few sentences at the most. Big decision makers are very busy people so you need to be brief until you get their attention.

I also attached an image of a flyer I had made, which featured a picture of the prototype of my product in use. Finally, I said I had a prototype sample I could happily send him.

Within a day, he replied. He thought it looked very interesting, and told me he was going to connect me with their head corporate buyer to discuss it further.

Needless to say, I was absolutely thrilled! To have a top executive at a multi-billion dollar retail corporation tell me my product was “very interesting” was a huge jolt of energy.

A few days later, I was in communication with their head retail buyer. I remember being quite pleased that I was referred to this buyer by his boss instead of someone lower in the company. It increased my confidence that he would be interested in my product.

NOTE: The term buyer may sound generic but that is the term most commonly used to refer to the decision makers at retail companies who decide which products they will carry.

He requested that I send him a sample which I was happy to do since I was confident he would be even more impressed once he actually used it.

So I quickly sent him my 3D-printed prototype. I was anxious and excited to hear his reaction to my product, crossing my fingers that Blockbuster would really be a fantastic fit.

The buyer received my sample, and it was time to talk with him on the phone. His response, let’s just say, was not what I hoped for.

I remember the chills running down my back when I asked him what he thought of the sample. His blunt answer? “It’s awkward to use.”

I was completely devastated by that response. I also didn’t understand why he thought it was “awkward” to use. How dare he say that, I thought!

I spent a day or two wallowing in self-pity, and then decided to go back and figure this out. I asked myself, “okay, why did he say this?”

I did some research and talked more with the Blockbuster buyer. I did my own experiments, and ultimately discovered exactly what had happened.

I had sent the Blockbuster buyer a 3D-printed prototype made with a type of plastic that does not respond well to high temperatures.

I had shipped the prototype to Dallas, Texas in the middle of a summer heat wave.

My prototype had sat in high heat, and warped or partially melted. It didn’t melt enough to be immediately obvious to the buyer, who had never seen the product before.

But the prototype plastic had melted enough to make the product awkward to turn on and off.

I mention this because it was critical that I eventually pushed through this obstacle. I worked with the buyer, even though I was devastated, and he was very accepting.

He knew it was a prototype, and not a production unit. I was able to work past this to eventually get a Letter Of Intent (an LOI) from Blockbuster.

An LOI isn’t a legal commitment to buy like a purchase order. My letter of intent just said, “We’re interested. We would like to test this product or carry this product in our stores once it’s available.”

I had achieved my end goal! The deliverable that I wanted from my first interactions with Blockbuster was merely a letter of intent.

Well, a purchase order would have been even better, but that’s extremely rare without having inventory ready to ship. My goal for this step was merely to get their written interest in my product, which I need to use for step three.

Step #3 – The Manufacturer

Next, I leveraged my prototype and my letter of intent from Blockbuster to find a manufacturing partner. First of all, I want to stress that this is not just a standard contract manufacturer available for hire, but a real partner invested in your success.

A contract manufacturer is a manufacturer for hire. You tell them, “I want you to make 10,000 of these,” and they will manufacture it for you. Some can be hybrids, but in general a contract manufacturer produces products for other companies and it doesn’t manufacture their own products.

I focused specifically on manufacturers that were not contract manufacturers because I knew a contract manufacturer would view my product as just another thing they’ll produce for payment.

I wanted a manufacturer that believed in my product enough to invest in it. It is also important that you find a manufacturer that is not operating at full capacity. This was key in my case.

It meant that some of their manufacturing resources were sitting around not being used. So it was in their best interest to try and bring on new products to manufacture, even if that required some investment on their part.

I also looked for manufacturers that operated in both the U.S. and China. I focused on U.S. manufacturers (since I live there) with wholly owned subsidiary factories in China.

This gave me many of the advantages of domestic manufacturing, but also the low pricing only available in China.

It also made it a little bit easier and less intimidating to deal with a “local” company versus a random company in far-away China.

I started with an online search for manufacturers that produced products with similar manufacturing requirements to my own. It doesn’t necessarily need to be the exact same market. But, you don’t want to approach a tire manufacturer to make your electronic product.

Look for manufacturers that have the basic equipment, skills and technologies to produce your product.

I began by emailing my list of potential manufacturers. Just like I did with Blockbuster, I included a flyer showing my product in use with a few key bullet points of text.

Of course, I also mentioned having a letter of intent from Blockbuster Video. I probably emailed several dozen manufacturers, and about half a dozen got back to me expressing some level of interest.

There was one manufacturer that really stood out. They essentially told me, “we get pitched products all the time by entrepreneurs, 99% of those we ignore, but we feel that your product, and the success you’ve had, warrants an exception.”

That’s how it started.

I lived in a small town in Alaska at the time, and the general manager of their Chinese factory ended up flying to Alaska to meet with me. Needless to say I was thrilled they believed in my product enough to personally come and meet with me.

Although, the general manager did sneak in a mini vacation while in Alaska so the trip was a good tax write-off for him too.

Shortly after that meeting we signed a formal agreement. The agreement helped me in quite a few ways. Like I said, this was much more than just a contract manufacturing relationship. This was a real business partnership.

Importantly, they let me use their engineering department to finalize my design and prepare it for mass manufacturing. That was huge.

I had taken my product pretty far, and I had all the main design requirements figured out. But there were a lot of small changes that needed to be done to get my product completely ready for mass manufacturing.

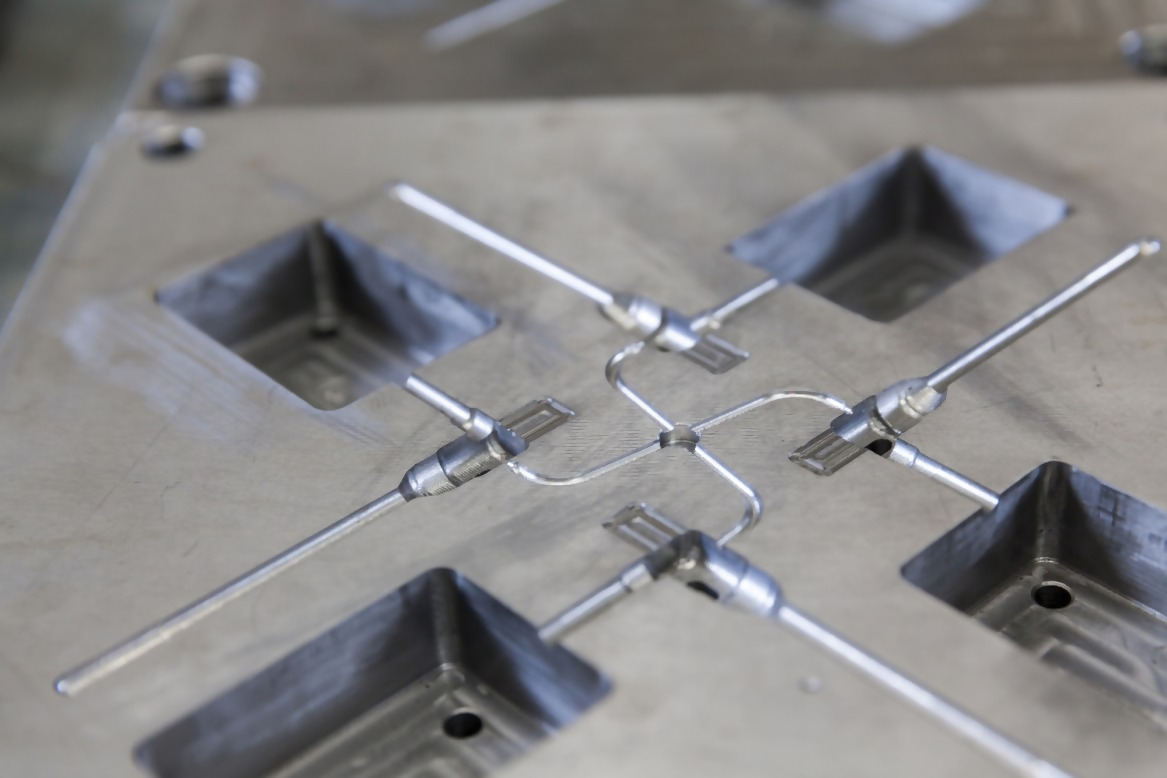

The second thing my manufacturing partner did for me was amortize my injection mold costs. The injection molds for my product were going to cost a little over $100,000.

Normally, I wouldn’t suggest going from a prototype stage directly to high-volume manufacturing using molds this expensive. You can purchase lower volume molds for a few thousand dollars each.

But in this case, the manufacturer felt so confident in my product that they wanted to finance the higher cost molds. I was fine with this, since they were the ones taking the large financial risk if my product ended up a failure.

They would pay upfront for the cost of the molds. Then, they would charge me $1 extra per unit for the first 100,000 units that I sold. This is called amortization.

This is a great arrangement, since it’s basically an interest-free loan that was essentially risk-free for me. It was a way to help fund the transition to manufacturing, that didn’t require I give away any equity in my company.

The manufacturer agreed to my terms because they wanted the business, they had an in-house engineering team with time available, and they had the money to spend. That was a really huge break for my young startup.

They also got an exclusive manufacturing agreement. This meant that I couldn’t go to another manufacturer for the first two years, or for the first million units, which ever happened first.

I thought this was still pretty lenient, since they could have required a much longer exclusive period.

The third hugely beneficial thing that my manufacturer did was fund all of my inventory. This was tremendously beneficial because it removed one of the biggest obstacles to scaling a hardware company – cash flow.

Cash flow for a hardware startup is one of the biggest obstacles to growth, and that’s because typically you have to pay your manufacturer upfront.

This means that after you pay the manufacturer, you have to wait several weeks for the product to be manufactured. Then, it takes several more weeks to ship the product to your country or the country of your customer.

For example, if it’s shipped by sea cargo from China to the US, then expect it to take three to four weeks. Then, you will need to ship it from the port (often LA) to your warehouse.

Finally, you deliver it to your retail customer, but the soonest a retailer will pay you is 30 days after they get the order. No, that is not a typo. Fair or not, that is how it is done.

Payment 60 days after receiving an order is also pretty common, and some retailers demand 90 to 120 days to pay you for their order.

The problem is, you have to pay for the manufacturing, the inventory, and the shipment to the customer. But, it will be at least three months until you finally get paid back. That really makes growth a challenge for any startup.

My manufacturing partner agreed to give me payment terms of 90 days. This gave me the time to wait for payment from my own customers before I had to pay the manufacturer.

Having a net 90-day payment term removed all those cash flow issues because I didn’t have to pay for anything until I was paid by the customer. That was absolutely huge!

Step #4 – Build a Sales Team

What if I told you that it was possible to build an army of sales people around the world, and that you only had to pay them if they actually sold your product?

Even better, you can pay them after the customer has paid you, so you don’t need to spend any money upfront.

This is all true if you choose to work with what are called independent sales representatives.

An independent sales rep is someone who takes on your product and sells it to their established list of companies or clients.

A big advantage is these salespeople already have established relationships with the key decision makers at some of the biggest companies. For instance, they may already have a relationship with a buyer at Walmart, Best Buy, Target, Amazon, etc.

They’ll have a much higher chance of success with retailers than if you approached their decision makers by yourself as a stranger.

As we all know, having existing relationships is really critical in business.

Professional sales people are not only out there selling your product, but they also provide extremely valuable feedback about your product, the industry standards, and how to improve your sales in general.

They are already working with various retailers, and they will sell your product to them in exchange for a commission, 10% is very standard.

Sales reps will go out, sell your product and get a purchase order. Your role is to manufacture the purchase order and to ship it to their customer.

Eventually, the customer will pay you. Only at this point do you have to pay the commission to the sales representative.

It really is an ideal situation, especially for a start up that cannot afford to bring on an in-house sales team. This is a way to grow a sales team without spending any money upfront.

When building your sales team you’ll now want to leverage your prototype, your early customer interest, and your manufacturer relationship in order to get sales people interested.

Sales reps are investing their time trying to sell your product, so it’s obviously a risk for them. If your product doesn’t sell, they don’t get paid.

Therefore, they only want to present products that are exciting and that they think will sell. They also have to protect their reputation with their existing retailer customers.

Having interest early on from a big customer, like I did with Blockbuster, makes a sales rep feel more confident about your product. They likely don’t want to be the first person ever to present the product to a retailer.

If you’ve already presented it to a large, national retailer, and they were interested, odds are the sales rep’s customers will be interested too.

Find a Lead Sales Representative

When first starting out, I focused on finding a lead sales representative. I wanted to find one person who just absolutely loved the product, had a huge amount of experience in the industry, and was someone I worked well with and liked.

Your lead sales rep should have excitement for your product and connections in your specific industry. But it’s important that you like them because you’re going to be working with them very closely.

My lead sales representative became almost like my business partner. We would talk nearly every day, so it was critical that we worked together well.

He really helped me understand the industry and the expected standards. He knew what all the big retailers would expect in regards to pricing, in store displays, and shipping requirements.

My lead sales rep filled me in on all the little details that only an inside player can know. Potential customers will take you much more seriously if you truly understand the industry and how to deliver what they want.

My lead sales rep also helped me finalize my retail packaging. I had a preliminary retail package at the time, but he had decades of experience selling products and seeing how they sell in the retail environment.

A sales rep’s entire income is driven by their ability to pick products that will sell well. Whereas, I had zero experience knowing what products sell and don’t sell.

My lead sales rep also helped me understand the cost structures and the expected margins for certain retailers. Whether you’re selling to a distributor or directly to the retailer, there are different pricing structures, so having someone with firsthand experience is really important.

I worked with him for probably four months while I was still finalizing the product, the retail packaging, and setting up manufacturing.

We worked really closely during that time to fine-tune everything for retail sales. Once we had everything ready, we started expanding and building up the sales team.

My lead sales rep helped me recruit other sales representatives. A few were reps he already had connections to, but most were reps that I found myself.

While interviewing dozens of sales reps, it was really beneficial to have a knowledgeable sales person serving as an advisor.

Eventually, my sales team included people that I had reached out to via email, some that were referred by my lead rep, and some that I met at a tradeshow.

We worked very closely together for months before I had anything that was ready to sell. It would have been very unfair to expect him to spend all this time working with me for just the potential of a commission many months down the road.

So I initially paid him a few hundred dollars a month for the first six months until we had sales. Then he started earning a real commission.

It was definitely worth a few hundred dollars a month, and was some of the best money I ever spent.

Ultimately, I ended up giving him a 15% commission on everything that he sold whereas all the other sales representatives got a 10% commission. He also got a 3% commission on any sales that either I made or other reps made.

Keep in mind that once you get up into really high volumes, you can typically scale back the commission rate into the single-digit range.

But when you’re first starting off, especially with an unproven product, you’re going to have to offer a higher than standard commission just to entice salespeople to come on board and take on the risk of a new product.

Also, be aware that sales representatives deal with very specific retailers that are typically headquartered in their region. For example, if they’re located in Boston, then they’re going to deal mostly with any retailers that have headquarters in that area.

When you’re building up your sales rep team, keep a list of all your target retailers and build your sales team up based on what geographic areas they cover.

In my business, I created a spreadsheet where I listed every single retail chain that I thought would be a good fit for my product. Then, I built my sales team based on what retailers they were working with already. I built out a team that covered all the different large retailers that I wanted to target.

There can be some overlap if your product is sold, say, in electronics stores and automotive stores. Then you might have multiple sales reps in the same area, one for automotive and one for electronics.

But in general, sales reps are split up on a geographical basis, so you don’t want too many in the same region, presenting to the same customers.

There is a professional association for sales representatives called the Manufacturers Agents National Association, or MANA. It’s a reputable organization that’s been around for a long time, and is a good way to search for sales representatives.

Don’t even consider trying to build an in-house sales team, unless one of your founders happens to be a sales person with a lot of experience.

Conclusion

Of course there were lots of little steps that I didn’t highlight in this article, but these are the four major steps I followed after I had done the upfront work necessary to prove my product was worth seriously pursuing.

The overall moral of this story is that success is all about the execution, not necessarily the idea. If you prove that you can execute, then more opportunities will present themselves.

My final advice is always to focus on taking lots of small steps building up leverage and confidence as you go. This is a much better strategy than taking giant leaps forward into the risky unknown.

Other content you may like:

- How To Sell Your New Product and Grow Your Revenue

- How to Price Your Product for Various Distribution Channels

- Manufacturer invested $100,000 in my product

- My New Product on Store Shelves – How I Screwed Up!

- Why You Need to Stop Over-Focusing on Your Product

“Execution” is subjective. When security is taken into consideration; when competition is taken into consideration; When exit strategy is taken into consideration; the benefit of being in stealth mode; The benefit of staying ahead of the competition… All these are important factors. Do you agree?

Hi John, This sounds like a perfect and typical route for a small scale tech company. Wouldn’t you agree that each project is a case by case scenario? Also, these contract Sales or channel sales options do not have reliability because they are selling a bunch of other things. They will be incentivized with what gets them money quickly which also means what we as a company can reliably deliver. Manufacturing and Supply Chain management with hardware is no joke regardless of how complicated the product is. The more complicated the more costly and involved. Do you agree?

The process to market is most definitely on a case by case scenario. There is no simple process that works identically the same for every project. You have to consider all of the various routes and then determine the best path for your own project. There are literally an infinite number of ways to do this. There is definitely no simple 1,2,3 step process that will work for every project. This is just the 4-step process I followed. Some elements of my process can be incorporated into your strategy but your overall strategy will be unique.

Yes, I couldn’t agree more. The more complicated the product the more costly it is to get to market. This is why I always encourage entrepreneurs to spend considerable time upfront focusing on ways to simplify their product.

Thanks for the comments as always!

Cheers,

John