Why Hardware is Hard, But Easier Than Ever

Hardware is hard is so commonly said it has become a cliché. Yeah, you know it’s hard, but why exactly? I will discuss this in detail in this article.

Fortunately, there is good news too – developing and launching a new hardware product is easier now than it’s ever been. There have been many advancements in recent years that make it much more feasible for an entrepreneur to bring a new hardware product to market.

Throughout this article, I’ll also share with you various strategies for surpassing the obstacles in your path to market.

Why Hardware is So Difficult

Development requires significant engineering expertise

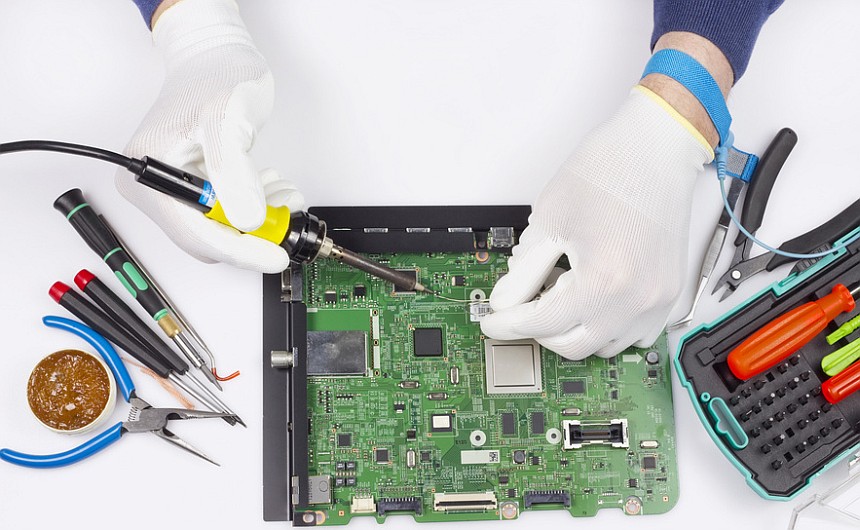

Creating a new software product can many times be accomplished by one good programmer. On the other hand, developing a hardware product encompasses multiple fields of engineering and computer science.

Most entrepreneurs don’t have all of the necessary expertise required to develop a new product. In fact, most engineers don’t have all of the required expertise.

Regardless of your background, you’re going to need to learn a lot about a wide variety of subjects. And you’re going to need to seek outside help to fill any holes in your areas of knowledge. For development, you’ll likely need an electronics engineer, a firmware programmer, a 3D designer, and perhaps a mobile app programmer.

Significant Capital is Required

Engineering fees, prototype expenses, and the high cost of injection molds create a significant barrier to entry for many hardware entrepreneurs. If you think you can bring a new product to market without any money you simply aren’t being realistic. Although the cost to bring a new hardware product to market has been greatly reduced due advancements I discuss shortly, it still requires some money to get started.

Unless you are in a very positive financial position your goal should likely be to self-fund your product’s development until you can get it far enough along that others will be interested in investing. This usually means a very high-quality prototype. The closer the prototype is to a production version of the product the more likely you will be to secure outside funding.

Here’s an article I wrote that describes in detail the costs required to develop, prototype, scale, and manufacturer your new electronic product.

Implementing market feedback is slow

So you have this awesome improvement you’d like to make to your product. Be prepared to wait at least 6 months to see it reach the market. Making product changes after manufacturing has begun is slow and expensive.

Not only must you modify your production process and ship the new product across an ocean, but you also must usually sell off any of your old inventory first. It’s a painfully slow process that makes reacting to market feedback challenging.

With my own product I found this also to be true for the retail package. I was constantly wanting to make improvements to the retail package to better convey the usefulness of the product, but this was frustratingly slow to accomplish. With software or an online business you can implement feedback much faster.

Manufacturing is complicated, especially offshore

Most entrepreneurs think once they have a fully working prototype that they are ready to go to market. Sorry, but this is far from the truth. The time, cost, and complexity of setting up mass manufacturing is probably the most underestimated step for launching a new hardware product. In most cases you can expect it to take an additional 6-12 months to get manufacturing up and running.

[clickToTweet tweet=”The cost & complexity to setup manufacturing is the most underestimated step for hardware startups.” quote=”The cost and complexity to setup manufacturing is the most underestimated step for hardware startups.”] Start by manufacturing your product domestically using a contract manufacturer. Only once you have domestic manufacturing running smoothly should you consider moving to an offshore factory.

Resolving production issues will be much more challenging when manufacturing offshore. So get all of the manufacturing issues worked out domestically before moving offshore. This includes at least the PCB production, injection molding of the enclosure, and the final product assembly. While manufacturing domestically you can still source many of the components from Asia to keep your product cost down.

Cash flow challenges – pay before you get paid

Once your product is developed, and manufacturing is running smoothly, then cash flow becomes your biggest obstacle moving forward. This is due to the fact that most manufacturers will require payment before shipping, yet it will be months before you get paid by your customers. You will have to finance your inventory for this interim time.

When selling directly to consumers through your website, it will probably take you several months to sell off your inventory. If you sell your product through retail stores, you won’t get paid by retailers for 30 to 90 days after you ship them your product. No retailer ever pays faster than 30 days.

If you can find a manufacturing partner willing to give you better payment terms it will greatly improve your cash flow. Most manufacturers won’t be willing to do this unless you’ve been manufacturing high volume with them for some time. Fortunately, there are exceptions.

For example, my manufacturing partner agreed to give me payment terms of net 90. Net 90 means I had 90 days after shipment to pay. This allowed me to get paid by my customers before I had to pay the manufacturer. This was a huge boost to cash flow. These are exceptionally rare payment terms, so don’t expect terms this fantastic. But if I can do it, so can you! That being said, anything is an improvement over having to pay the manufacturer 100% upfront.

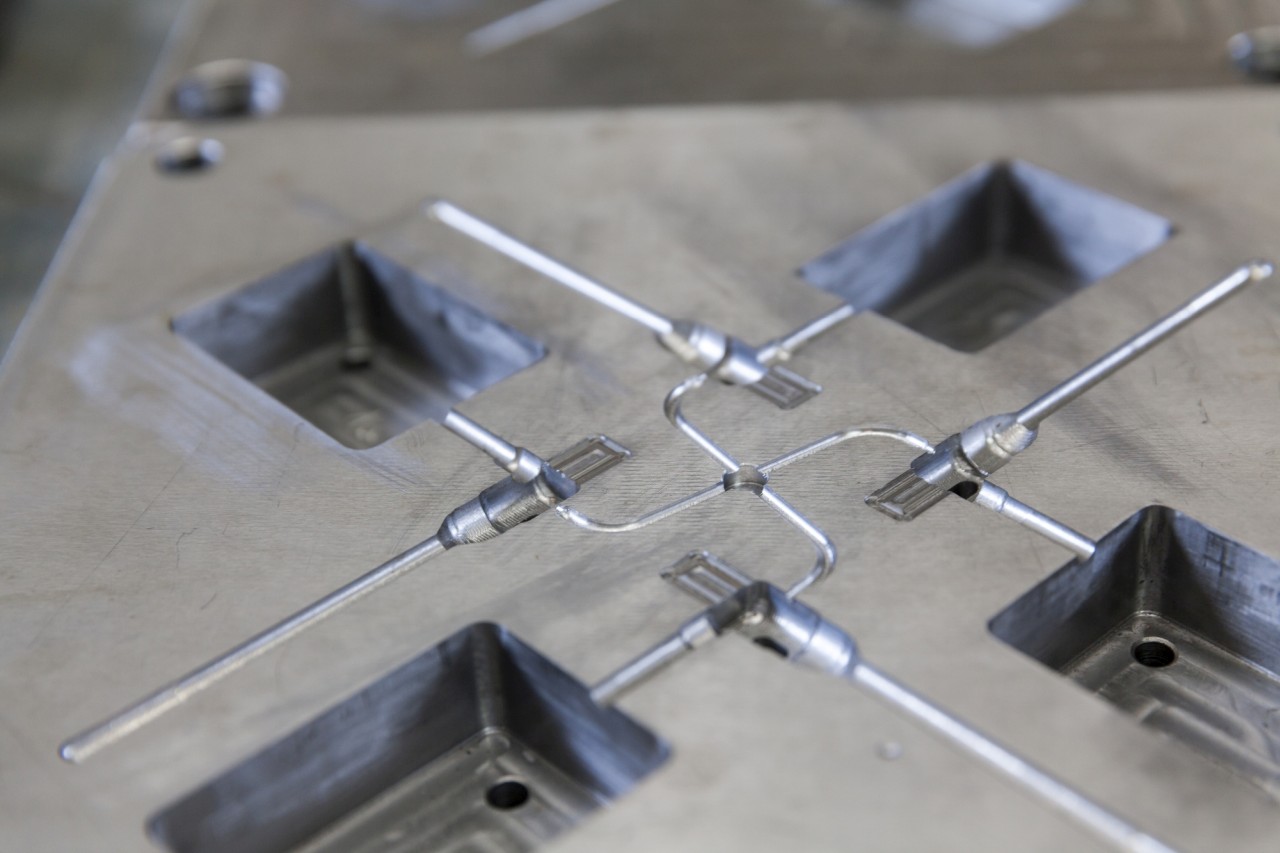

Injection molds

As complex as the electronics may be, the plastic enclosure for your product will be the most costly part to scale to large volume manufacturing. This is because the production of custom shaped plastic pieces requires the use of an ancient manufacturing technology called injection molding.

Injection molds are expensive, really expensive. Most of this cost is related to the hardness of the mold’s metal, and the number of cavities in the mold. Softer metals are more easily machined into the desired mold shape.

Making a soft metal mold is your cheapest option, and will cost around a few thousand dollars. However, softer molds degrade quickly and are therefore limited to smaller production quantities of usually a few thousand units. Harder metals are significantly more expensive (tens of thousands of dollars) and are used for higher volume production.

The number of cavities determines how many parts can be produced at one time. Normally you start with a single cavity mold and then work up from there as your production volume increases. Multiple cavity molds cost much more, but they lower your cost per part and speed up manufacturing time.

Why Hardware is Easier Than Ever

Widespread availability of outsourcing

Hardware entrepreneurs today have a critical resource at their disposal that wasn’t widely available to entrepreneurs in the past: freelancers. Developing and launching a new electronic product requires such a wide variety of skills that it’s not possible for one person to do it all alone.

Thanks to the ever growing freelancer economy, entrepreneurs now have an entire world of skilled professionals available to them.

No need to develop custom components

Just about every type of electronic component you can imagine is now broadly available. There should be no need to develop a custom component. If your product absolutely requires one then you should consider pursuing a different product, unless you have a large team and significant capital. Developing a new component or technology is beyond the financial means of most entrepreneurs.

Widespread use of wireless radio modules

In the past, anyone developing a product with wireless functionality had to design a custom wireless radio. Designing a wireless circuit can be incredibly tricky, and requires specialized knowledge that most electrical engineers lack. A new wireless circuit can be very challenging to get right the first time. They also need to be precisely tuned to achieve maximum performance, and that tuning process requires very expensive equipment.

The other big downside of having to design a custom radio is the FCC certification cost. Any new electronic product will require FCC certification. But there are two types of FCC certification with very different costs. A product incorporating a custom wireless circuit will be classified as an intentional radiator. This type of certification will cost a minimum of $10,000.

On the other hand, by using pre-certified modules for any wireless functions your product can be classified as a non-intentional radiator. This type of FCC certification will cost only about $1,500. Wireless modules significantly reduce your development complexity, cost, time, and risk.

No need to setup your own factory

Entrepreneurs wishing to bring a physical product to market in the old days had to also setup their own factory. Talk about a huge obstacle! Not only did you have to develop a product but you also had to develop the manufacturing processes to produce that product.

Fortunately, this is no longer true. An entrepreneur today who sets up their own factory is crazy! Today we have contract manufacturers. Contract manufacturers can be paid to manufacture any product that matches their manufacturing capabilities. For you, that likely means finding a manufacturer specializing in consumer electronic products.

Less capital is required

The wide availability of freelancers, the lack of a need to develop any custom electronic components, the use of contract manufacturers, and the use of pre-certified wireless modules all mean that you need less capital now than in the past. Not only is less capital required but you also have more ways to raise it.

More options to raise money

Crowdfunding is a huge benefit for today’s hardware entrepreneurs. Not only does crowdfunding offer you a way to raise capital, but it’s also a fantastic way to get market feedback.

The only type of market feedback that really matters is actual sales. Normally, you need to have manufacturing up and running before you can ever get real sales data. But with crowdfunding you can gain this valuable feedback before you manufacture your product.

More ways to sell your product

Getting a new product in retail chains is a Herculean effort. You have to first build up considerable proof that your product will sell well. In the past, this usually meant you started selling your product in local mom-and-pop stores. But small, local, retail stores are mostly a thing of the past so they are no longer a realistic option.

Fortunately, for many reasons, hardware entrepreneurs have the power of the internet to help them today. The internet opens up numerous avenues to get early sales proof for your product.

Your best option is selling your product on your own website. This will give you the highest profit margins since no one else (other than your manufacturer) is getting a piece of the pie. Selling on your own website also gives you the most control and the best market feedback since you’ll be communicating with the end user directly.

More ways to market your product

The internet comes to the rescue again. Getting the word out about your product is so much easier today than in the past. It can also be significantly cheaper since paid advertising is now only one of many marketing strategies.

With social media and Google it’s possible for you to get the word out about your product without spending a fortune. Of course, by being essentially free it also means it’s many times more difficult. Paid advertising is fast and easy but expensive. Organic marketing is cheap but difficult and slow.

Even with all the new ways to market your product, don’t underestimate the difficulty of marketing a new product (see 13 Reasons Why Hardware Startups Fail). The adage “Build it and they will come” is most definitely not true for new products. You need to make marketing a priority from day one.

More resources are available

Fortunately, there are thousands of websites discussing essential topics like entrepreneurship, product development, electronics design, 3D printing, marketing, and manufacturing.

You no longer have to go at it all alone. In the past, being a hardware entrepreneur meant being a real maverick. That’s still true to some extent, but today you have at your fingertips an endless number of experts, resources and tools that can help make your hardware product a reality.

Hardware will always be hard, but it’s easier now than ever. Also, remember that being difficult isn’t necessarily a bad thing. It creates a larger barrier to entry so you don’t have to worry as much about another startup stealing your market share.

Now is a fantastic time to be a hardware entrepreneur. So get that idea out of your head and on the market!

Great content!!., but I have a question.

You said in the manufacturing section that it could potentially take up to 6-12 months for manufacturing up and running.

What are the reasons for that to happen?

Thanks!.

Thanks Jahanzeb, I’m glad this article was helpful.

The 6-12 months time frame is driven by several things. First of all, making thousands, or especially hundreds of thousands or even millions of a product, is a whole lot different than making just one or two. Each time you increase your production volume (and especially when going from a few prototypes to full manufacturing) new problems always pop up. These problems take time to find and correct.

Also the enclosure design used for prototyping (3D printed) almost always needs significant improvements to get it optimized for injection molding.

The 6-12 months time frame was also assuming manufacturing in China. It always takes a lot longer to setup manufacturing in Asia than it does to do it domestically. Part of the delay is the time it takes to manufacture your high-pressure injection molds to manufacturer your product’s enclosure. High volume molds can take several months to get made. This time frame is closer to 6 months or less if you setup production domestically for just making a few thousand units.

Also you have the delay of obtaining electrical certifications. These need to be done before you setup manufacturing, and this process can take several months, especially if you fail the certification testing the first time and must make design changes (very common).

Okay, hope that clarifies it better for you.

Thanks,

John