From Prototype to Mass Manufacturing: Understanding Scaling Costs for Physical Products

The most underestimated part of bringing a hardware product to market is scaling costs. Use this article to accurately forecast every cost associated with bringing your product from prototype to mass manufacturing in Asia.

Scaling a physical product means taking it from a few prototypes all the way to mass manufacturing it.

Having a final prototype version of your product is exciting and is a huge accomplishment. Congratulations, you have made it past development and are now ready to scale! However, you are still a long way from being ready to sell your product.

In this article I break down the scaling costs into three groups: electrical certifications, manufacturing setup costs, and miscellaneous costs that include patents, insurance, and audits.

Technically electrical certifications aren’t legally required to manufacture a product, only to sell it.

However, you should always obtain certifications before you begin mass manufacturing a product since design changes will likely be required. For this reason I always consider certifications to be part of the scaling process.

Types of prototypes

So there is no confusion in this article when I say a prototype I mean a production-quality prototype.

A production-quality prototype, as the name implies, is a prototype that is fundamentally designed for mass manufacturing. It’s very close to the final product you will eventually ship to customers.

A proof of concept prototype (works-like prototype) comes much earlier in the process and cannot be scaled to mass manufacturing in most cases, although it is legal to take a product to market that has an Arduino embedded in it.

However, the cost and the size of an Arduino rarely makes it a viable solution for bringing to market.

Development kits like Arduino and Raspberry Pi are great for early Proof-of-Concept prototypes, but not for mass manufacturing.

If you are still at the proof-of-concept stage then that means you are still in the development phase of bringing your product to market. The scaling phase begins once you have the custom production-quality prototype.

Time from prototype to mass manufacturing

I typically find the time required to go from idea to final prototype is similar to the time it takes to go from prototype all the way to mass manufacturing. So once you have your production-quality prototype you are approximately half way to market.

In the best case scenario – and don’t ever count on the best case scenario because it rarely happens in reality – you’re looking at a minimum of six months of development time and another six months of scaling for mass manufacturing.

That’s a year from idea to being ready for mass manufacturing. That’s the best case scenario, and it’s extremely rare for a product to be able to get to market faster than that. More realistically it will take 16-18 months to go from idea to market for most hardware products.

The exact timeline obviously depends on your skills and your cash. If you have a full team of engineers and programmers, then you’re going to move faster than someone that doesn’t have a large team and is outsourcing the development.

The slowest case is when you have no money or experience, forcing you to learn new skills in order to proceed. But the slow way can be the right way in many cases.

Electrical certifications

One of the major costs for scaling a product is the electrical certifications. Legally this must be done before selling your product, but practically it needs to be done before manufacturing starts.

Let’s break this down into each of the certifications you will likely require for your product:

FCC certification

For the US, one of the primary certifications you’re going to need is FCC certification. The purpose of FCC certification is to make sure your product isn’t emitting electromagnetic radiation radio waves that are going to interfere with other forms of communication.

Any electrical product that uses circuits oscillating at 9 kHz or higher requires FCC certification. This includes almost any electronic product.

For example, if you have a microcontroller in your product then it’s probably going to operate much faster than only 9 kHz (most operate at MHz speeds). Some microcontrollers can operate below 9kHz in applications that require very slow processing time. This is one way to avoid FCC certification, but that is quite rare. 99% of the products I’ve worked on require some level of FCC certification if sold in the U.S or Canada.

Let’s assume that you will need FCC certification, and that you’ve got things operating above 9kHz. Then, the key criteria becomes whether or not your product is classified as an intentional radiator or a non-intentional radiator.

An intentional radiator, as the name implies, is a product that’s designed to intentionally radiate electromagnetic radiation or radio waves. This is a technical way to say a “wireless” product. If for example, the product emits Bluetooth or WiFi radio waves, then it’s considered an intentional radiator.

The other classification is a non-intentional radiator. If your product doesn’t have any wireless functionality then it’s considered a non-intentional radiator.

Non-intentional radiator products will radiate some small level of electromagnetic interference that has to be measured and FCC certified. But the level will be much lower than a product purposefully designed to emit radio waves.

These two classifications are important because it’s much cheaper to certify a non-intentional radiator than an intentional radiator.

$2,500 is a fairly typical cost to obtain non-intentional radiator certification. That cost climbs up to a minimum of $10,000 as soon as your product is classified as an intentional radiator.

Fortunately for most products that are wireless, you can still get by with non-intentional radiator certification by using pre-certified modules for any wireless functionality.

There are two ways you can incorporate wireless functionality into your product. You can custom design a circuit based on a discrete radio transceiver chip. If you go that route, the product is going to be considered an intentional radiator, so it’s going to be a lot more expensive to certify.

However, you can also use a pre-certified wireless module instead of a custom chip-based circuit. A pre-certified module allows your product to still be classified as non-intentional even though you have wireless functionality.

There are several reasons for using modules. Modules lower your certification cost and reduce your development costs, development risks and the time it takes to develop the product. You will get to market faster and cheaper by using modules.

The downside is that modules will increase your manufacturing cost. However, it typically doesn’t make financial sense to go with a custom solution until you are up to producing at least 100,000 units or more.

You need to be at a high production volume before the savings on your manufacturing costs offset all the extra upfront certification costs.

When bringing a product to market I always advise that you focus on reducing your development risks and costs first. Later after the product is on the market, you can focus on improving your profit margins.

UL/CSA certification

Next comes the UL (Underwriters Laboratories) and CSA (Canadian Standards Association) certifications. Both certifications are essentially equivalent. You can have either UL or CSA certification, since either is accepted in the US and Canada.

This certification is mandatory for any product that plugs directly into an AC electrical outlet. As most of us know, AC electricity can be dangerous and therefore requires extra certifications.

You can get around this certification by using a pre-certified AC/DC solution. For instance, you could use a standard, off-the-shelf USB charger that is already pre-certified and outputs 5VDC. Since your product never comes into direct contact with the AC electricity you will not require UL certification.

I find that unless you’re doing something where you have AC motors or some type of AC component in the product, which is fairly rare, then you should use a pre-certified AC/DC module or adapter.

If it is a better fit for your product, you can also totally embed a pre-certified AC-DC adapter inside your product, instead of using an external wall adapter. This will still allow you to bypass the UL/CSA certification.

Certifications for lithium batteries

The other certification cost involves rechargeable lithium batteries. Most of us know that lithium batteries can be dangerous. If they’re not treated properly, they can explode or catch on fire.

Lithium-ion batteries can be potentially dangerous and require special safety certifications.

In the past, UL 1642 was one of the primary certifications that you needed. But that’s been phased out and replaced by the IEC 62133 certification.

There’s also a third certification called UN 38.3. It usually costs less than $1,000. This certification is for shipping the batteries because there are restrictions on shipping lithium batteries.

If you can initially use a battery that already has the IEC 62133 and the UN 38.3 certification (and potentially the UL 1642), that will reduce your certification costs.

Sometimes though you need to have a custom battery designed just for your product so you can take advantage of every bit of available space and maximize the battery life. In that case you will be responsible for obtaining these battery certifications.

CE certification

CE is an abbreviation for the French phrase Conformité Européenne which translates to European Conformity. CE certification is only required if you plan to sell your product in Europe.

The CE marking is a manufacturer’s declaration that a product complies with the safety, health, and environmental requirements for Europe. CE is sort of a combination of FCC and UL certifications required in the U.S. and Canada.

RoHS

RoHS certification is required to show that your product is free of lead. This certification is currently only required in Europe and the U.S. state of California.

Even though in the U.S. it’s only required in a single state, California’s market is so huge that most companies selling products in the U.S. elect to obtain RoHS certification.

You don’t want to be in the position of selling one version of your product in California, and then another uncertified version outside of California. Most companies just get this certification regardless of whether or not they’re going to sell in California immediately.

On a positive note, RoHS is one of the lower cost certifications that you will need to obtain.

Bluetooth

The last certification to discuss is really a licensing fee that is required if your product uses Bluetooth. Bluetooth is a trademark, so in order to say your product uses Bluetooth, you will have to pay a licensing fee.

In the past, for established companies the fee was $8,000 and for early startups it was only $2,500. But as of early 2019 the startup discount has been eliminated and now startups have to pay the full fee.

This fee is required if you use a Bluetooth module or a Bluetooth chip, so using a Bluetooth module doesn’t allow you to bypass this fee. However, there is a way to completely avoid the Bluetooth fee which I share inside the Hardware Academy.

Manufacturing setup costs

Molds

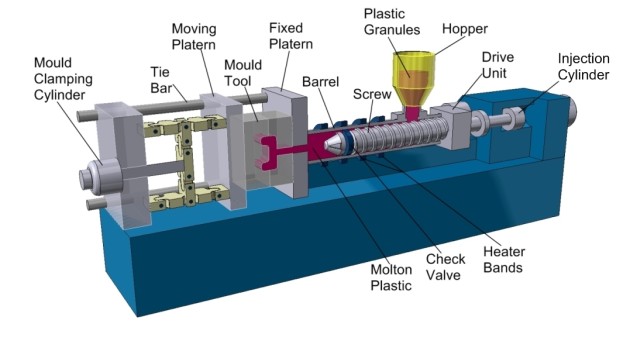

Each custom shaped plastic part required for your product will need its own separate high-pressure injection mold. Most products will require two or more molds, since enclosures at a minimum consist of a top side and a bottom side.

These injection molds can be really expensive. You can start off paying less for molds made out of softer metals like aluminum, but they will only last for the production of a few thousand units.

ProtoMold is a good place to purchase lower cost aluminum molds to get you started. Simple aluminum molds start around $1,500. Keep in mind this cost will be for each custom piece of plastic. If your product requires four custom pieces of plastic, you will need four aluminum molds at $1,500 each for a total mold cost of $6,000.

As soon as you start increasing the volume of parts that you’re producing you have to do two things.

First, you need to use a harder metal so the mold can withstand the production of thousands, or even millions, of parts.

Pictorial of an injection molding machine. Image supplied by Rutland Plastics.

Second, you will increase the number of cavities in each mold. When you first start off, you’ll use a single cavity mold. Each time that mold is filled with plastic, it shoots out one part.

To increase your manufacturing capacity and lower your manufacturing unit cost, you’ll eventually want to start using multi-cavity molds.

No matter how great you think your product is you don’t want to start with high volume production molds. Remember, high volume molds can be crazy expensive. If you find a problem with the mold, then it’s much harder and expensive to fix.

I recommend starting with aluminum molds designed for making a few thousand parts. Chances are you will discover various improvements for your product after you make a couple thousand units.

You can make those improvements and then step up to a harder steel once you need to produce say 50,000 units or more.

From there you can step up to a multi-cavity, hard steel mold that’s made to produce hundreds of thousands, or millions of units. Once you get up to multi-cavity steel molds, you’re looking at spending $10,000 to $50,000 per mold. If you require complex molds with side actions the cost can be even higher.

Example of a high-pressure injection mold used for mass manufacturing plastic parts.

Molds tend to be one of the biggest costs when scaling a hardware product. Fortunately, you don’t need to do this all at one time and you can ramp up in stages.

Start with low cost single-cavity aluminum molds, sell some product, and then ramp up slowly from there. Start off taking small steps so if you have to back up and improve something in your product and/or mold, it’s not going to cost as much.

Single cavity, aluminum molds can produce up to about 10,000 parts. Medium volume production over 10,000 units will require a single cavity, steel mold. Higher volume production, in the hundreds of thousands of units, is going to require multi-cavity molds made of a harder grade of steel.

Don’t forget, you also have the injection molds required to produce your product’s retail package. So if you’re using a clam shell that custom fits your product, or a custom plastic insert that’s in a retail box that holds each of your components, those have to be molded as well and that also requires injection molds.

To learn more about injection molding see this blog and check out this paid course.

Assembly fixtures and other setup fees

In addition to molds there are also what are called assembly fixtures. Assembly fixtures are custom tools created to help simplify the product assembly.

There are also going to be other setup costs such as those associated with the assembly of your product’s printed circuit board.

However, these costs tend to cost significantly less than molds. Most of the manufacturing setup cost will be for the injection molds.

Patents, insurance, and audits

Patents

I’ve written in the past about the pros and cons of getting a patent. You’re looking at $10,000 or more for a utility patent. There are also other forms of intellectual property protection, such as trademarks and copyrights, that you should probably consider.

Trademarks and copyrights are not quite as good as having a patent on your product but, a trademark and a copyright are much cheaper forms of protection. You can use this to your advantage. Trademarks and copyrights cost hundreds of dollars, in contrast to patents that cost thousands or tens of thousands of dollars.

Product liability insurance

Another cost to anticipate is product liability insurance. I don’t care how safe your product is, you absolutely must have product liability insurance. No retailer will even consider selling a product that doesn’t have liability insurance.

Even if you only sell your product on your website, you should still get insurance. If a child were to choke on a small part from your product, you could easily be sued.

The price of product liability insurance will depend on your forecasted annual sales revenue and how risky the product may be to cause injury.

The average cost of liability insurance to use as a starting point estimate is about 26 cents per $100 in sales. You need to reach out to product liability insurance companies to get estimates for your specific product.

Factory and supplier audits

Finally, you should audit your factory at some point. This is probably not necessary for your domestic low-volume manufacturing, but you should visit and audit your long-term contract manufacturer in China.

You don’t want to just pick a random factory and trust them to manufacturer a quality product. You don’t of course need to audit every supplier, but I would recommend you audit the primary factory that will assemble and ship your product. Ultimately that factory is what controls the quality of product shipped to your customers.

You can also hire a third-party company to perform this audit for you if flying to China doesn’t sound appealing or you don’t feel you have the necessary experience. However, it really is more ideal if you can personally visit the factory.

Conclusion

In conclusion, your final scaling cost needs to include all of the electrical certification costs required for your market area, your manufacturing setup costs – which includes the molds and assembly fixtures – and any miscellaneous costs like patents, liability insurance, and factory audits.

Do not make the mistake of underestimating the cost and effort to scale your product from a prototype to a mass manufactured product ready to flood the market.

Costing estimation of new product development is a very crucial factor that needs to be handled with care. Thanks for such detailed article.

Great summary about certifications and thanks for sharing ways to legally go around them, this can definitely save you lots at the beginning. Would you know if these certifications are mandatory if you are crowdfunding your product through kickstater? It is a way to sort of sell the product after all.

Thanks John!

Hi Roberto,

Thanks for the comment. Yes they should be required before you ship the product.

All it takes is money to start .you are loaded and full of knowladge and idears.

Thanks John, as always very clear and easily understandable summary of the process. I alway enjoy reading your stuff and always find a nugget or two (or more) of gold that I can refer to as I try and act like I know what I’m doing 😉

Thank you Dave, I really appreciate your feedback.